Welcome to Xuchang Huarui Machinery Co.,Ltd.

| Availability: | |

|---|---|

| Quantity: | |

Product Introduction:

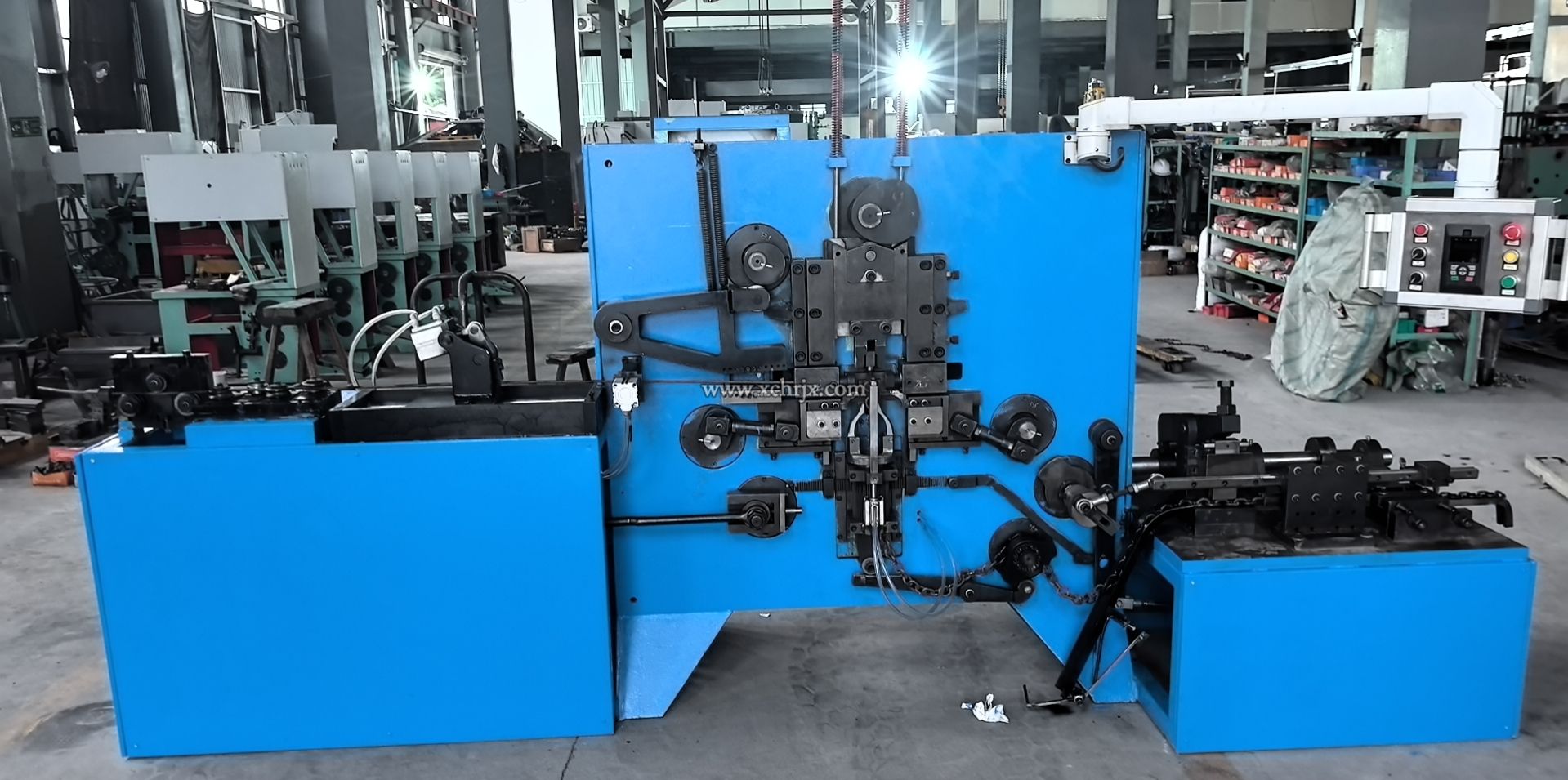

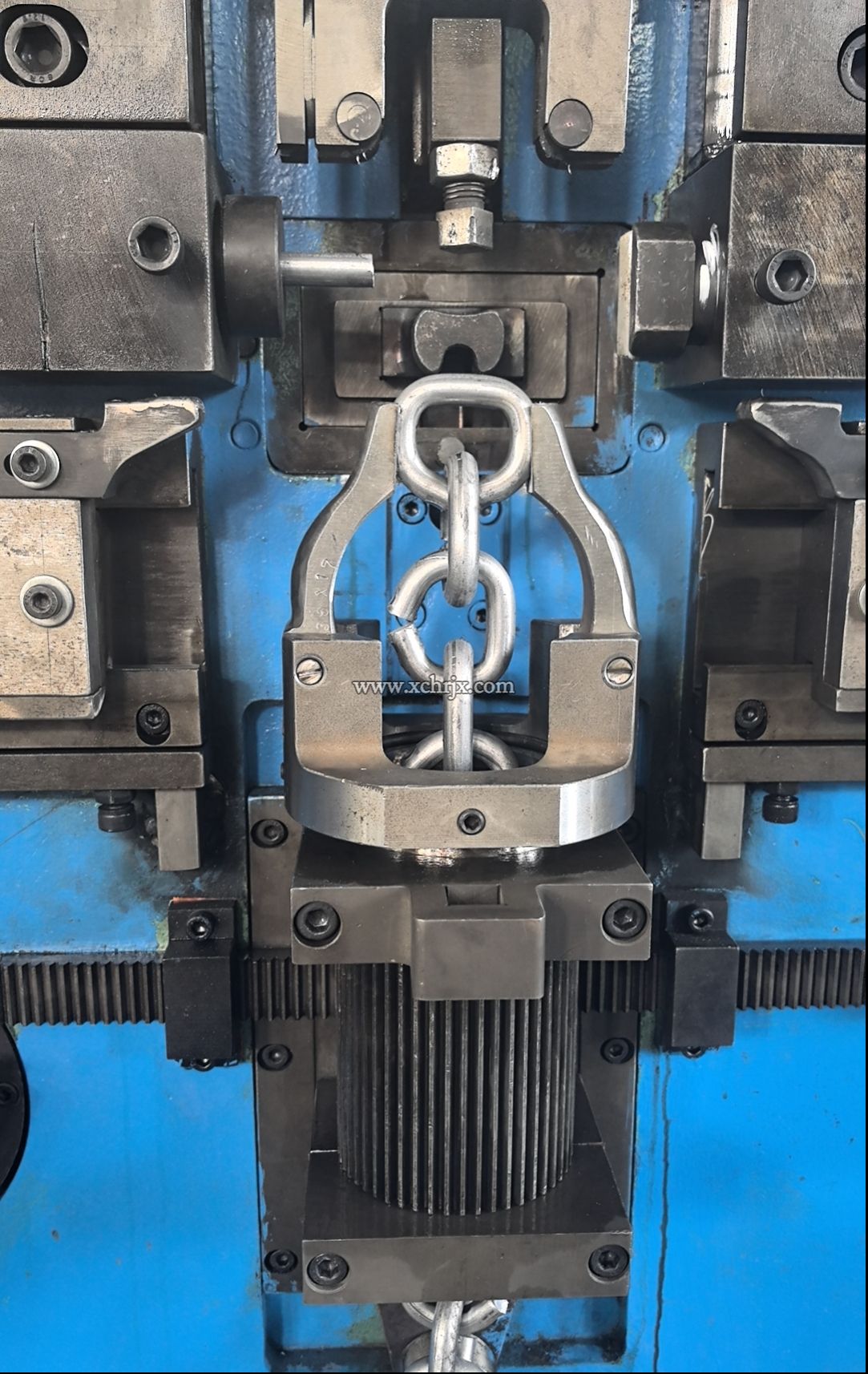

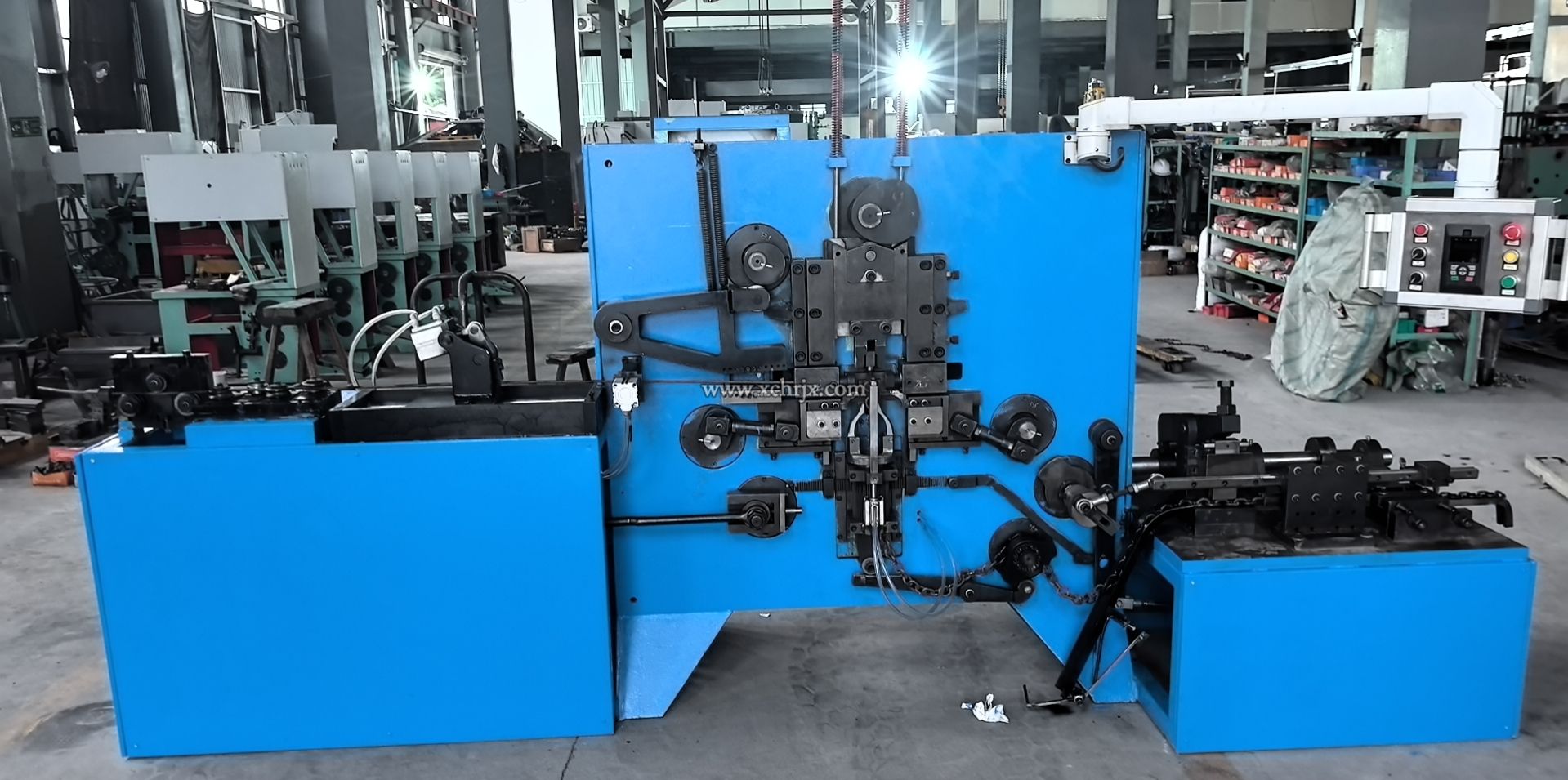

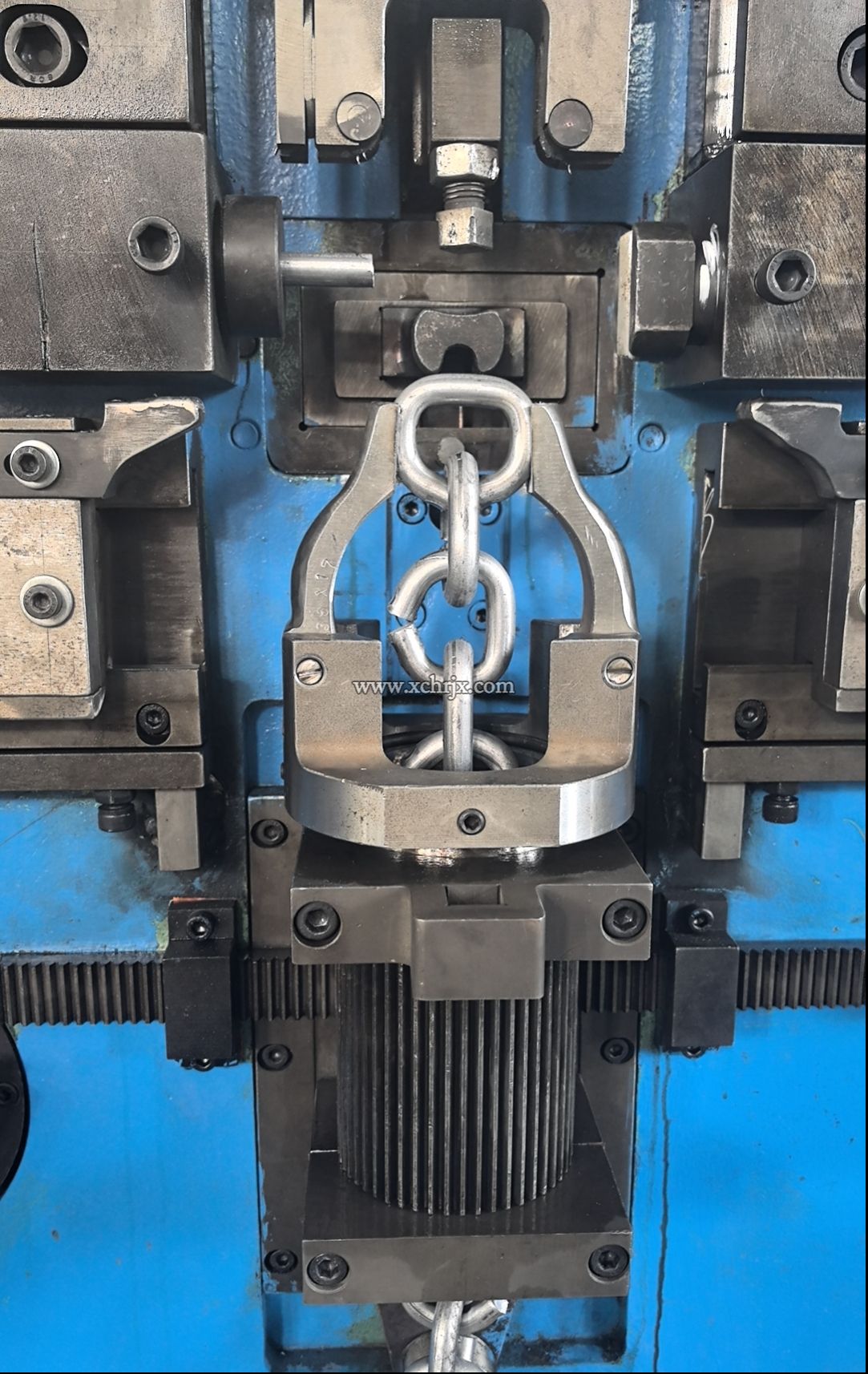

1- The core function of a Link chain braiding/weaving/bending/forming machine is to straighten, cut, and bend coiled metal wire into metal links, then automatically connect and arrange them according to specific structures and specifications to form industrial chains with transmission, traction, or load-bearing functions.

2- The core function of chain welding machines/chain butt welding machines/automatic chain welding machines is to melt and fuse the metal interfaces of the chain using heat energy (flash butt welding) to achieve a metallurgical-grade strong connection.

Both often work together: the chain braiding machine completes the initial assembly of the chain, while the chain welding machine strengthens the welding of critical joints, ensuring that the final product meets high-strength and high-safety industrial standards

.In addition, we have various auxiliary equipment of chain twisting machine, chain cutting machine, chain polishing machine, etc. Please contact us for more details.

Detailed pictures:

Advantages

* Frequency controller:

1- Stable current: Because the instantaneous current required by the welding machine is relatively large, it can make the current more stable.It is especially suitable for situations where the local current is stable.

2- More electricity power saving.

3- Better welding effect.

* Chain bending machine and welding machine come with inverter, so you can adjust speed of machine, it is easier to adjust machine for making chains in different wire diameter.

* Chain bending machine adopts a reducer transmission system, which is more stable and durable, more efficient, more precise and has a lower failure rate.

* Automated Chain Production Line: Replacing traditional manual assembly, it automates the feeding, bending, shaping, and welding of chain links, significantly improving production efficiency and consistency. It is suitable for the large-scale manufacturing of standard load-bearing chains, lifting chains, etc.

* Precise Chain Weaving Machine: Based on design requirements, it precisely controls the shape, spacing, and overall length of chain links, ensuring the chain meets the stringent standards of various heavy-duty conveying applications (such as mines and ports).

* Chain Welding process: Employing flash butt welding technology, the metal is instantly heated to a plastic state by a strong current, and then pressure is applied to complete the welding, resulting in high weld strength and minimal deformation. It also features an automatic deburring function,as a deburring chain welding machine, producing strong, aesthetically pleasing, smooth, and reliable chain links.

* Automation level:Our chain welding machines are equipped with PLC control, automatic centering, and frequency conversion speed regulation. The welding center distance error can be controlled within ±0.2mm, supporting continuous and efficient production.

Technical Parameters

Model | Wire diameter range | Productive | Motor power | Machine dimension | Weight |

DLJ4 | Φ2-4mm | 47-70rings/min | 1.5KW | 2100*700*1500mm | 580kg |

DLJ6 | Φ3-6mm | 45-65rings/min | 2.2KW | 2200*750*1600mm | 680kg |

DLJ8 | Φ4-8mm | 36-47rings/min | 3KW | 2500*850*1700mm | 1200kg |

DLJ10 | Φ5-10mm | 32-45rings/min | 5.5KW | 2700*900*1900mm | 2000kg |

DLJ13 | Φ7-13mm | 18-30rings/min | 7.5KW | 2900*1100*2100mm | 3000kg |

DLJ16 | Φ10-16mm | 13-22rings/min | 11KW | 3200*1100*2100mm | 4500kg |

DLJ20 | Φ13-20mm | 13-20rings/min | 15KW | 3800*1600*2400mm | 6500kg |

DLJ25 | Φ16-24mm | 13-18rings/min | 22KW | 4500*1800*2500mm | 9000kg |

Model | Wire diameter range | Productive | Transformer rated power | Motor power | Machine dimension | Weight |

40QMHJ | Φ2-4.5mm | 45-60rings/min | 40KVA | 1.1KW | 1145*810*1560mm | 700kg |

50QMHJ | Φ3-6mm | 42-56rings/min | 75KVA | 1.5KW | 1380x920*1740mm | 1200kg |

75QMHJ | Φ4-8mm | 38-50rings/min | 100KVA | 2.2KW | 1500*1000*1780mm | 1500kg |

100QMHJ | Φ6-10mm | 33-45rings/min | 125KVA | 3KW | 1600*1100*1780mm | 1800kg |

125QMHJ | Φ8-13mm | 28-38rings/min | 150KVA | 4KW | 1650*1160*1780mm | 2100kg |

150QMHJ | Φ10-16mm | 20-25rings/min | 200KVA | 5.5KW | 1960*1250*1850mm | 3200kg |

200QMHJ | Φ13-20mm | 18-23rings/min | 300KVA | 7.5kw | 2060*1360*2050mm | 4500kg |

250QMHJ | Φ16-24mm | 15-20rings/min | 600KA | 11KW | 236*1560*2150mm | 6000kg |

Product uses:

Our chain production equipment can automatically form and weld links ranging from 2-24mm. We can produce lifting chains and marine/mining connecting chains made of carbon steel, alloy steel, and stainless steel, with a wide range of applications and reliable quality.

We can customize molds according to your chain size and shape to meet your various production and usage needs.

FAQ

Q: Do you offer customize service?

A: Yes, we can customize machine according to your demands.

Q: How can I pay my order?

A: We accept T/T, LC,Western Union, Alibaba Online Payment to pay.

Q: Can you ship your machine to my country?

A: Yes, if you don't have shipping agent , we can ship machines to your nearest sea port.

Q: How many years exporting experience?

A: We have more than 16 years exporting experience, and we’ve exported our machines to more than 50 countries.

Q: Do you have any certificate?

A: We have CE certificate.

Q: How about your warranty?

A: 2 years. Normally, the general after-sale service may be as below.

1) The technical support is permanent.

2) The paid spares parts could be provided at any time,

3) Offer compensable installation and training service.

Product Introduction:

1- The core function of a Link chain braiding/weaving/bending/forming machine is to straighten, cut, and bend coiled metal wire into metal links, then automatically connect and arrange them according to specific structures and specifications to form industrial chains with transmission, traction, or load-bearing functions.

2- The core function of chain welding machines/chain butt welding machines/automatic chain welding machines is to melt and fuse the metal interfaces of the chain using heat energy (flash butt welding) to achieve a metallurgical-grade strong connection.

Both often work together: the chain braiding machine completes the initial assembly of the chain, while the chain welding machine strengthens the welding of critical joints, ensuring that the final product meets high-strength and high-safety industrial standards

.In addition, we have various auxiliary equipment of chain twisting machine, chain cutting machine, chain polishing machine, etc. Please contact us for more details.

Detailed pictures:

Advantages

* Frequency controller:

1- Stable current: Because the instantaneous current required by the welding machine is relatively large, it can make the current more stable.It is especially suitable for situations where the local current is stable.

2- More electricity power saving.

3- Better welding effect.

* Chain bending machine and welding machine come with inverter, so you can adjust speed of machine, it is easier to adjust machine for making chains in different wire diameter.

* Chain bending machine adopts a reducer transmission system, which is more stable and durable, more efficient, more precise and has a lower failure rate.

* Automated Chain Production Line: Replacing traditional manual assembly, it automates the feeding, bending, shaping, and welding of chain links, significantly improving production efficiency and consistency. It is suitable for the large-scale manufacturing of standard load-bearing chains, lifting chains, etc.

* Precise Chain Weaving Machine: Based on design requirements, it precisely controls the shape, spacing, and overall length of chain links, ensuring the chain meets the stringent standards of various heavy-duty conveying applications (such as mines and ports).

* Chain Welding process: Employing flash butt welding technology, the metal is instantly heated to a plastic state by a strong current, and then pressure is applied to complete the welding, resulting in high weld strength and minimal deformation. It also features an automatic deburring function,as a deburring chain welding machine, producing strong, aesthetically pleasing, smooth, and reliable chain links.

* Automation level:Our chain welding machines are equipped with PLC control, automatic centering, and frequency conversion speed regulation. The welding center distance error can be controlled within ±0.2mm, supporting continuous and efficient production.

Technical Parameters

Model | Wire diameter range | Productive | Motor power | Machine dimension | Weight |

DLJ4 | Φ2-4mm | 47-70rings/min | 1.5KW | 2100*700*1500mm | 580kg |

DLJ6 | Φ3-6mm | 45-65rings/min | 2.2KW | 2200*750*1600mm | 680kg |

DLJ8 | Φ4-8mm | 36-47rings/min | 3KW | 2500*850*1700mm | 1200kg |

DLJ10 | Φ5-10mm | 32-45rings/min | 5.5KW | 2700*900*1900mm | 2000kg |

DLJ13 | Φ7-13mm | 18-30rings/min | 7.5KW | 2900*1100*2100mm | 3000kg |

DLJ16 | Φ10-16mm | 13-22rings/min | 11KW | 3200*1100*2100mm | 4500kg |

DLJ20 | Φ13-20mm | 13-20rings/min | 15KW | 3800*1600*2400mm | 6500kg |

DLJ25 | Φ16-24mm | 13-18rings/min | 22KW | 4500*1800*2500mm | 9000kg |

Model | Wire diameter range | Productive | Transformer rated power | Motor power | Machine dimension | Weight |

40QMHJ | Φ2-4.5mm | 45-60rings/min | 40KVA | 1.1KW | 1145*810*1560mm | 700kg |

50QMHJ | Φ3-6mm | 42-56rings/min | 75KVA | 1.5KW | 1380x920*1740mm | 1200kg |

75QMHJ | Φ4-8mm | 38-50rings/min | 100KVA | 2.2KW | 1500*1000*1780mm | 1500kg |

100QMHJ | Φ6-10mm | 33-45rings/min | 125KVA | 3KW | 1600*1100*1780mm | 1800kg |

125QMHJ | Φ8-13mm | 28-38rings/min | 150KVA | 4KW | 1650*1160*1780mm | 2100kg |

150QMHJ | Φ10-16mm | 20-25rings/min | 200KVA | 5.5KW | 1960*1250*1850mm | 3200kg |

200QMHJ | Φ13-20mm | 18-23rings/min | 300KVA | 7.5kw | 2060*1360*2050mm | 4500kg |

250QMHJ | Φ16-24mm | 15-20rings/min | 600KA | 11KW | 236*1560*2150mm | 6000kg |

Product uses:

Our chain production equipment can automatically form and weld links ranging from 2-24mm. We can produce lifting chains and marine/mining connecting chains made of carbon steel, alloy steel, and stainless steel, with a wide range of applications and reliable quality.

We can customize molds according to your chain size and shape to meet your various production and usage needs.

FAQ

Q: Do you offer customize service?

A: Yes, we can customize machine according to your demands.

Q: How can I pay my order?

A: We accept T/T, LC,Western Union, Alibaba Online Payment to pay.

Q: Can you ship your machine to my country?

A: Yes, if you don't have shipping agent , we can ship machines to your nearest sea port.

Q: How many years exporting experience?

A: We have more than 16 years exporting experience, and we’ve exported our machines to more than 50 countries.

Q: Do you have any certificate?

A: We have CE certificate.

Q: How about your warranty?

A: 2 years. Normally, the general after-sale service may be as below.

1) The technical support is permanent.

2) The paid spares parts could be provided at any time,

3) Offer compensable installation and training service.