Welcome to Xuchang Huarui Machinery Co.,Ltd.

| Availability: | |

|---|---|

| Quantity: | |

HR14-130L

Huarui

High quality self drilling screw making machine

Product description

This equipment adopts cam surface design, does not affect the processing of forming the molding cycle time, can extend the time of stamping, and reduce the air travel time, to achieve good characteristics of the movement to ensure that mold life.

Advantages of self drilling screw making machine:

1. HRC60 ° grinding precision, rolling friction wear less, perfect zero backlash curve.

2. High-speed no noise, no energy waste.

3. High precision, OPR, absolute synchronization.

4. Simple structure Screw drive, very few failures.

Main technical parameters

Model | HR14-130L |

Speed | 120-520PCS/Minute |

Main Motor | 7.5KW(10HP) |

Oil pump motor | 0.75KW(1HP) |

elevator motor | 0.2KW(1/4HP) |

Inverter | 7.5KW |

Brake System | Air-Pressure Clutch |

Auto-action controller | PLC Controller |

Abnormal auto-action | Automatically detect abnormal man-machine interface display |

Vibrator Feeder | 620mm,Plus Silent PU Gelatin Spraying |

Wire Diameter | #6(2.8)~#14(5.45) |

Screw Length | 9.5mm~130mm |

Machine Size(L*W*H) | 1950mm* 1650mm*1650mm |

Machine weight | (approx)2180KG |

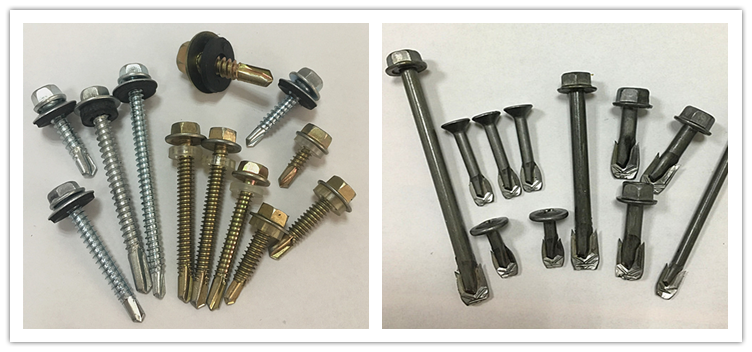

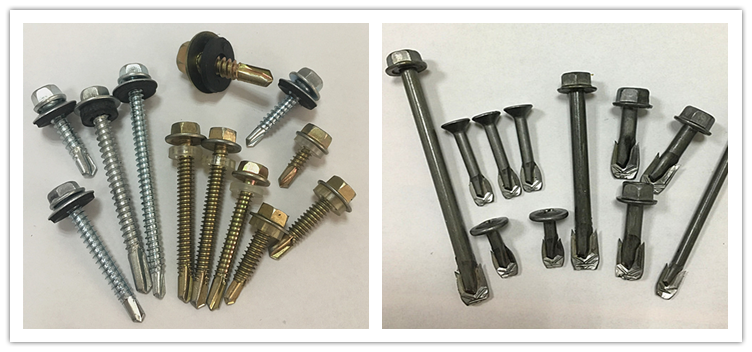

Product display

Self drilling screw pictures

After sales service:

1. The warranty time of all our products is two years.

2. Before sending the machines, they will be tested and adjusted, so you can use machines directly when you get it. Operation video & instruction will also be sent to clients.

3. Professional advice will be offered when you meet some problems when using our products.

4. All kinds of frequently used parts are supplied all the year round.

5. 24 hours on line service.

High quality self drilling screw making machine

Product description

This equipment adopts cam surface design, does not affect the processing of forming the molding cycle time, can extend the time of stamping, and reduce the air travel time, to achieve good characteristics of the movement to ensure that mold life.

Advantages of self drilling screw making machine:

1. HRC60 ° grinding precision, rolling friction wear less, perfect zero backlash curve.

2. High-speed no noise, no energy waste.

3. High precision, OPR, absolute synchronization.

4. Simple structure Screw drive, very few failures.

Main technical parameters

Model | HR14-130L |

Speed | 120-520PCS/Minute |

Main Motor | 7.5KW(10HP) |

Oil pump motor | 0.75KW(1HP) |

elevator motor | 0.2KW(1/4HP) |

Inverter | 7.5KW |

Brake System | Air-Pressure Clutch |

Auto-action controller | PLC Controller |

Abnormal auto-action | Automatically detect abnormal man-machine interface display |

Vibrator Feeder | 620mm,Plus Silent PU Gelatin Spraying |

Wire Diameter | #6(2.8)~#14(5.45) |

Screw Length | 9.5mm~130mm |

Machine Size(L*W*H) | 1950mm* 1650mm*1650mm |

Machine weight | (approx)2180KG |

Product display

Self drilling screw pictures

After sales service:

1. The warranty time of all our products is two years.

2. Before sending the machines, they will be tested and adjusted, so you can use machines directly when you get it. Operation video & instruction will also be sent to clients.

3. Professional advice will be offered when you meet some problems when using our products.

4. All kinds of frequently used parts are supplied all the year round.

5. 24 hours on line service.