Welcome to Xuchang Huarui Machinery Co.,Ltd.

| Availability: | |

|---|---|

| Quantity: | |

Product Introduction

Fully automatic rebar straightening and cutting machine is a metal wire processing equipment, also named as a wire straightening machine, bar straightening and cutting machine, CNC rebar straightening and cutting machine, Rebar Straightener and Cutter, Steel Bar Straightening & Cutting Machine, etc. It mainly processes coiled round rebar, coiled spiral rebar, and threaded rebar with diameters of Φ2-Φ16 mm, and can also process stainless steel wire, aluminum wire, cold-drawn wire, etc.

Our machine is equipped with a frequency converter, which can achieve 0-100m/min frequency conversion speed regulation, making it a high-speed rebar straightening and cutting machine.

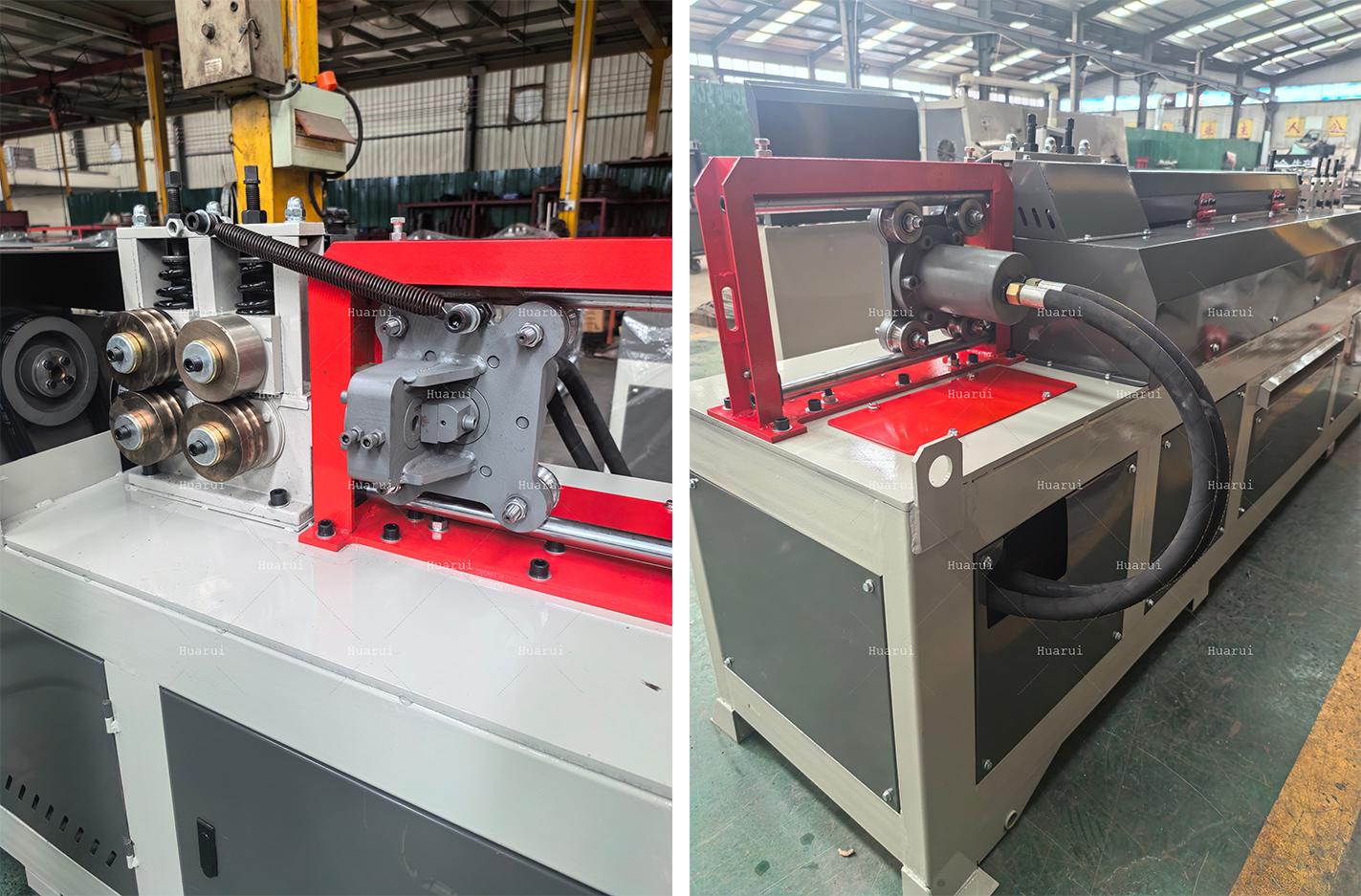

Machine Core Components and Advantages: The Steel Bar CNC Straightening Cutting Machine consists of five main parts: a straightening mechanism, a traction mechanism, a cutting mechanism, a material unloading rack, and an electrical control system. Modern models generally adopt microcomputer/PLC control, hydraulic or wheel shear cutting, and servo motor traction.

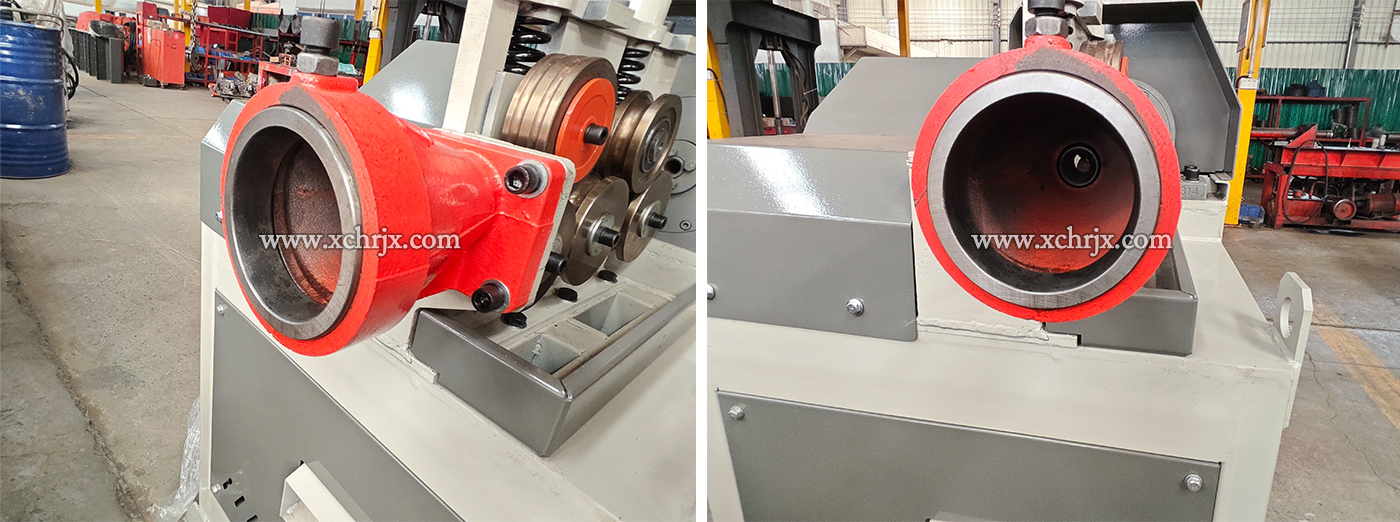

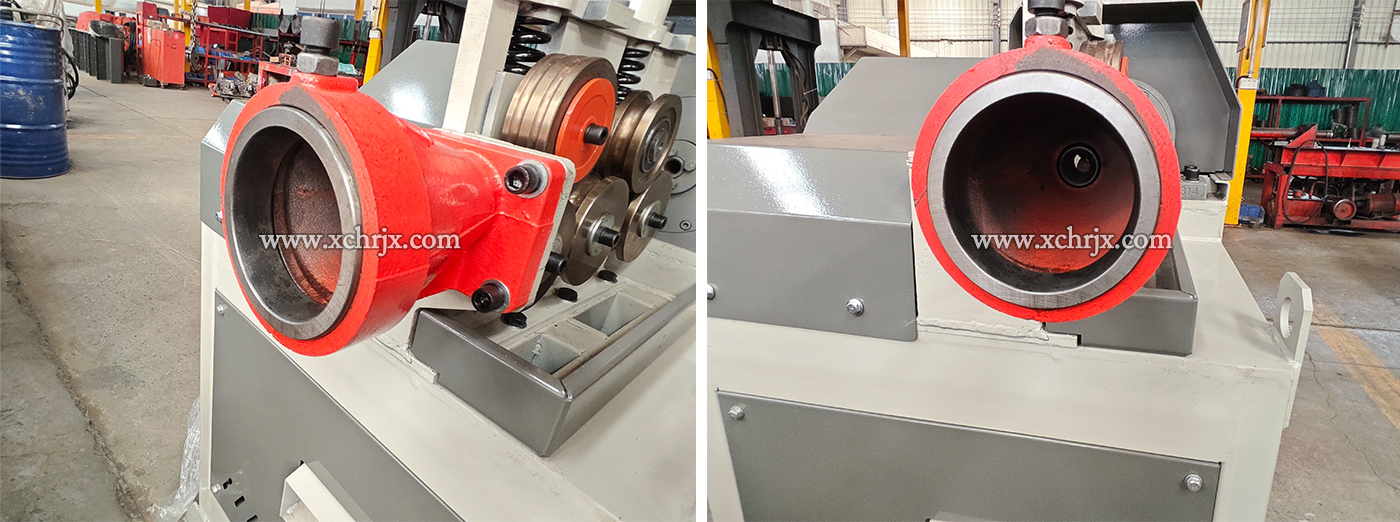

Specially customized feed inlet

Prevent the steel bars from swinging and tangling, resulting in better stability.

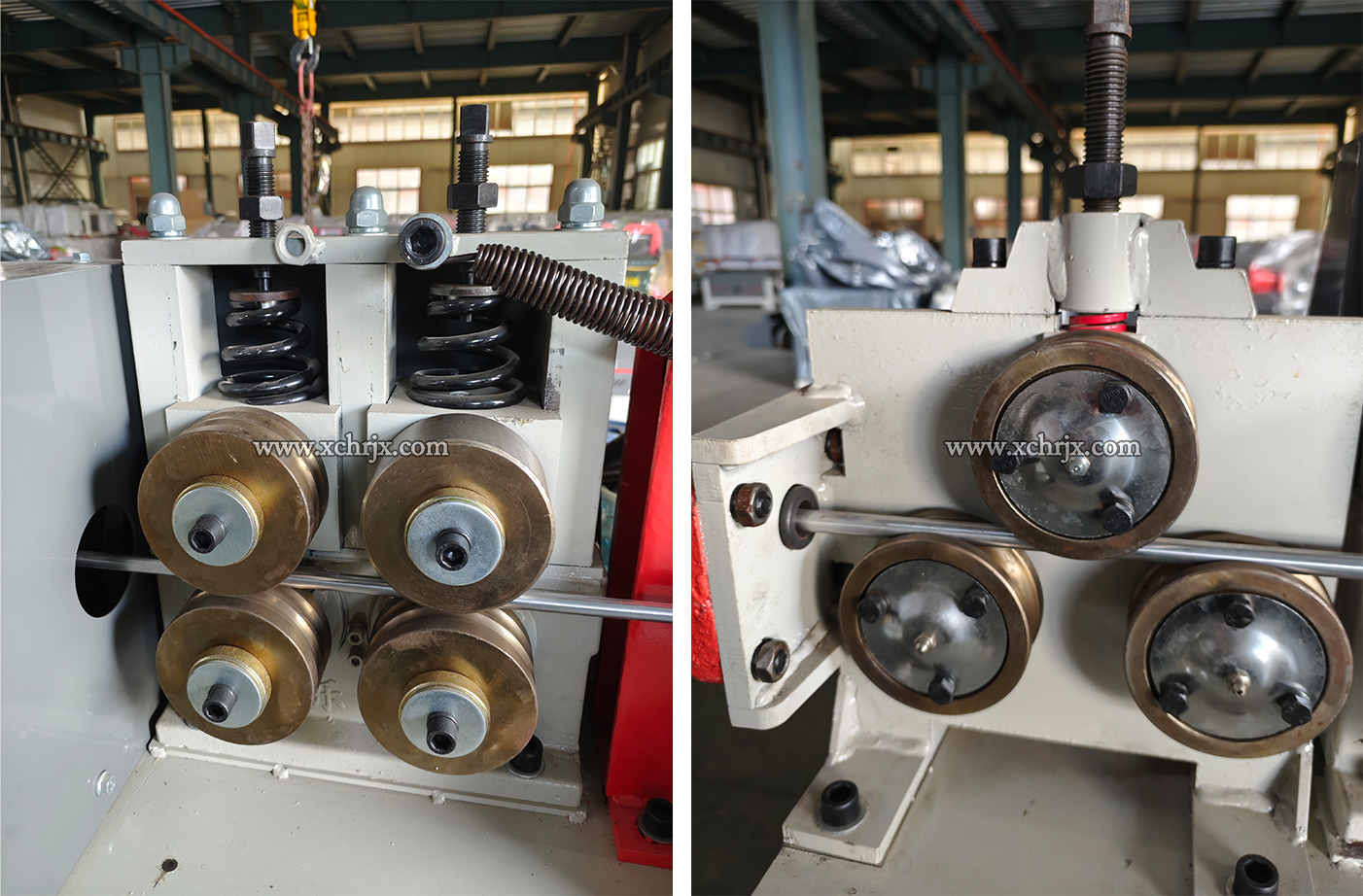

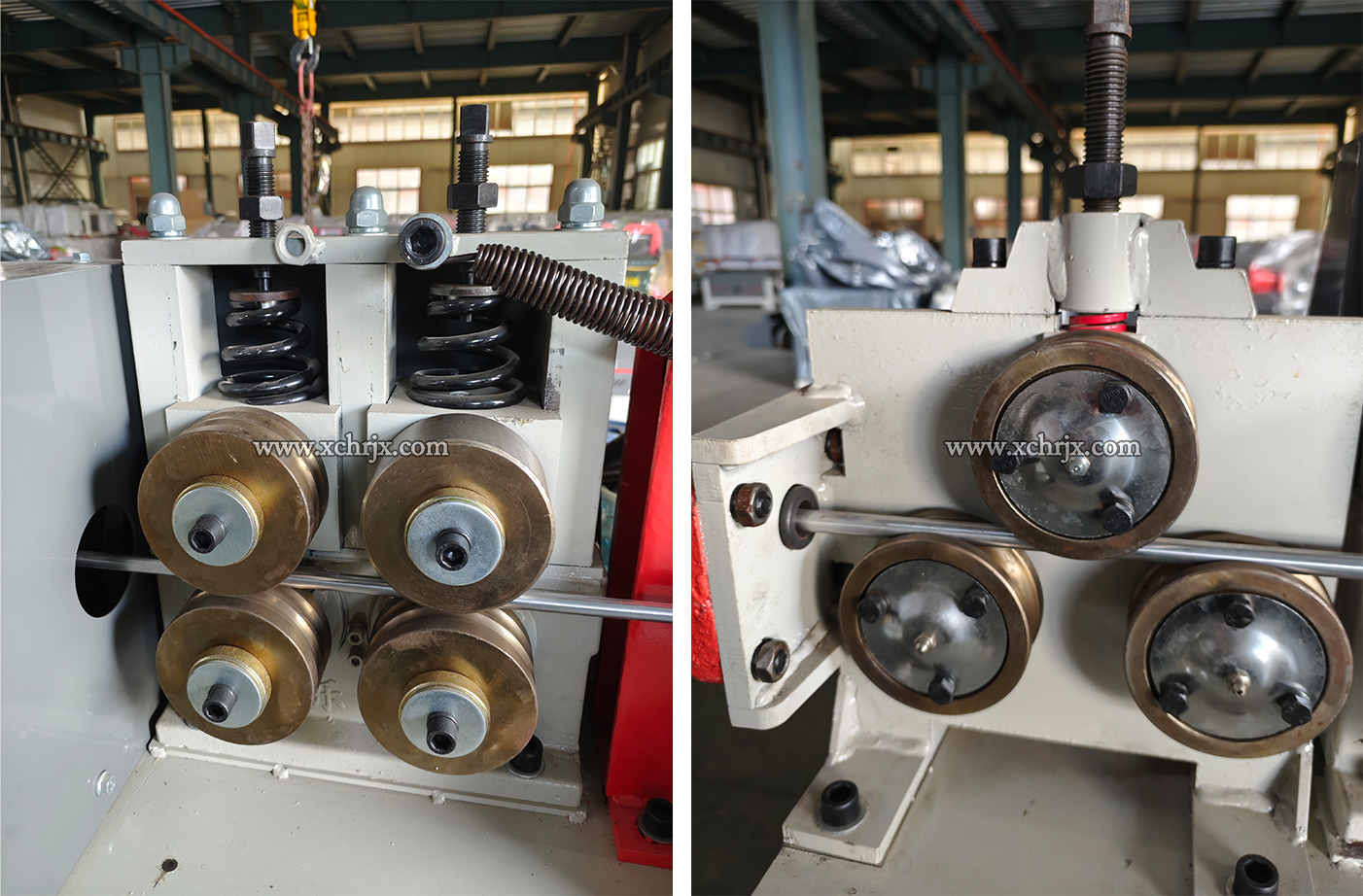

Traction Mechanism

Made of alloy, it is wear-resistant and durable, and the auxiliary straightening mechanism achieves better straightening effect.

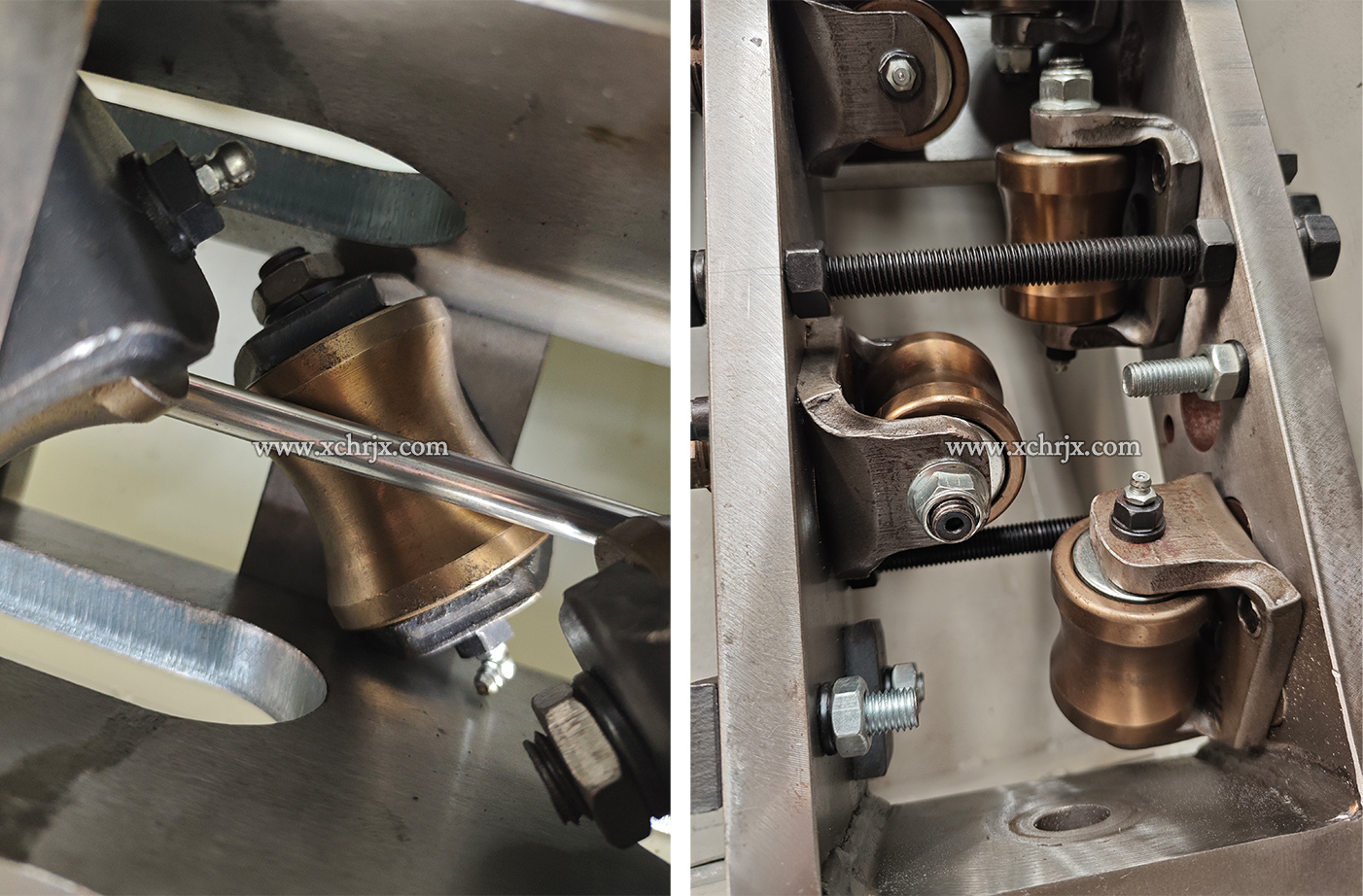

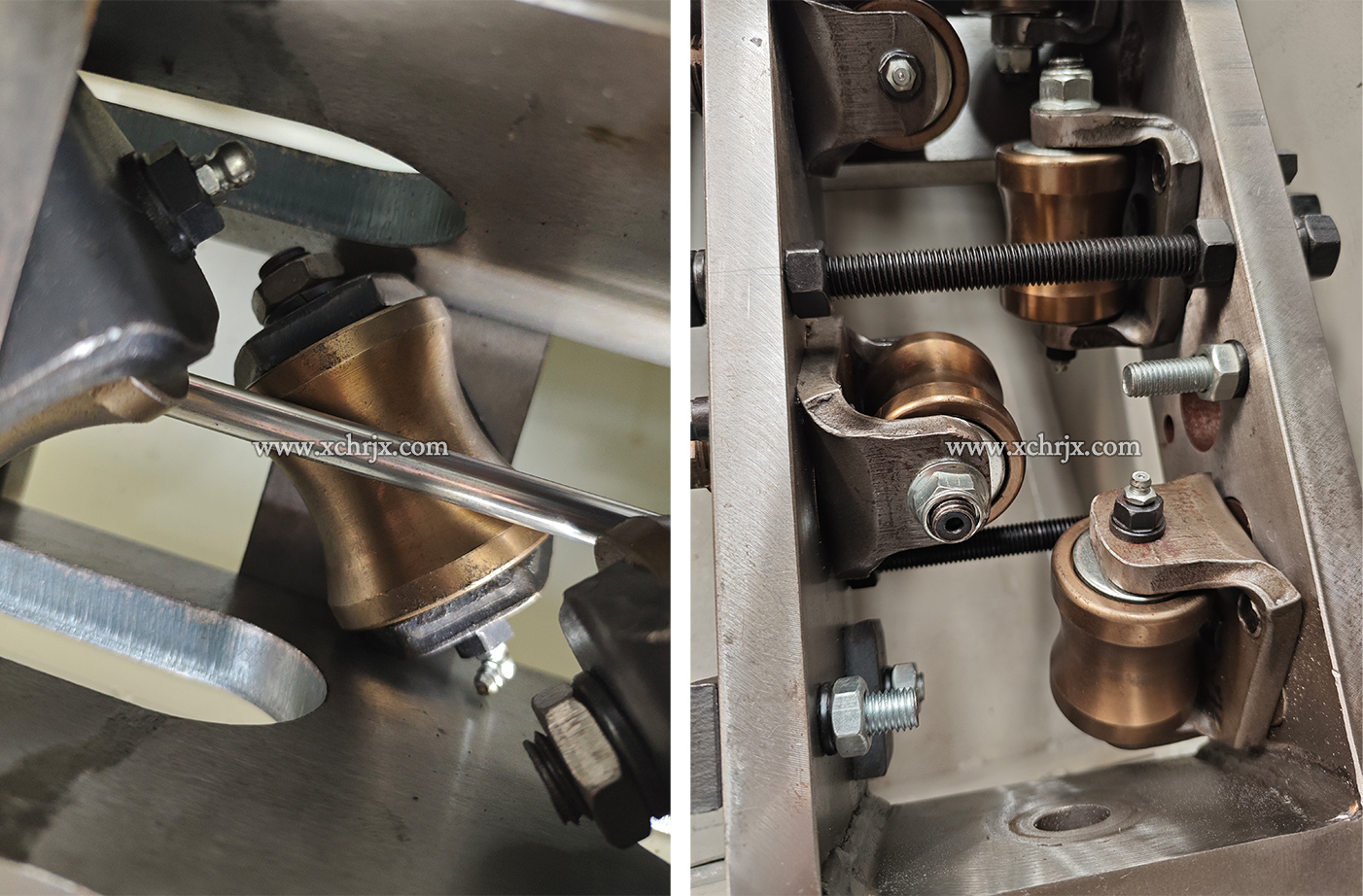

Straightening Mechanism

The straightening wheel is made of Cr12mov material and processed by vacuum heat treatment. It has a built-in dust-proof design to prevent oxide scale from damaging the bearing and is more durable.

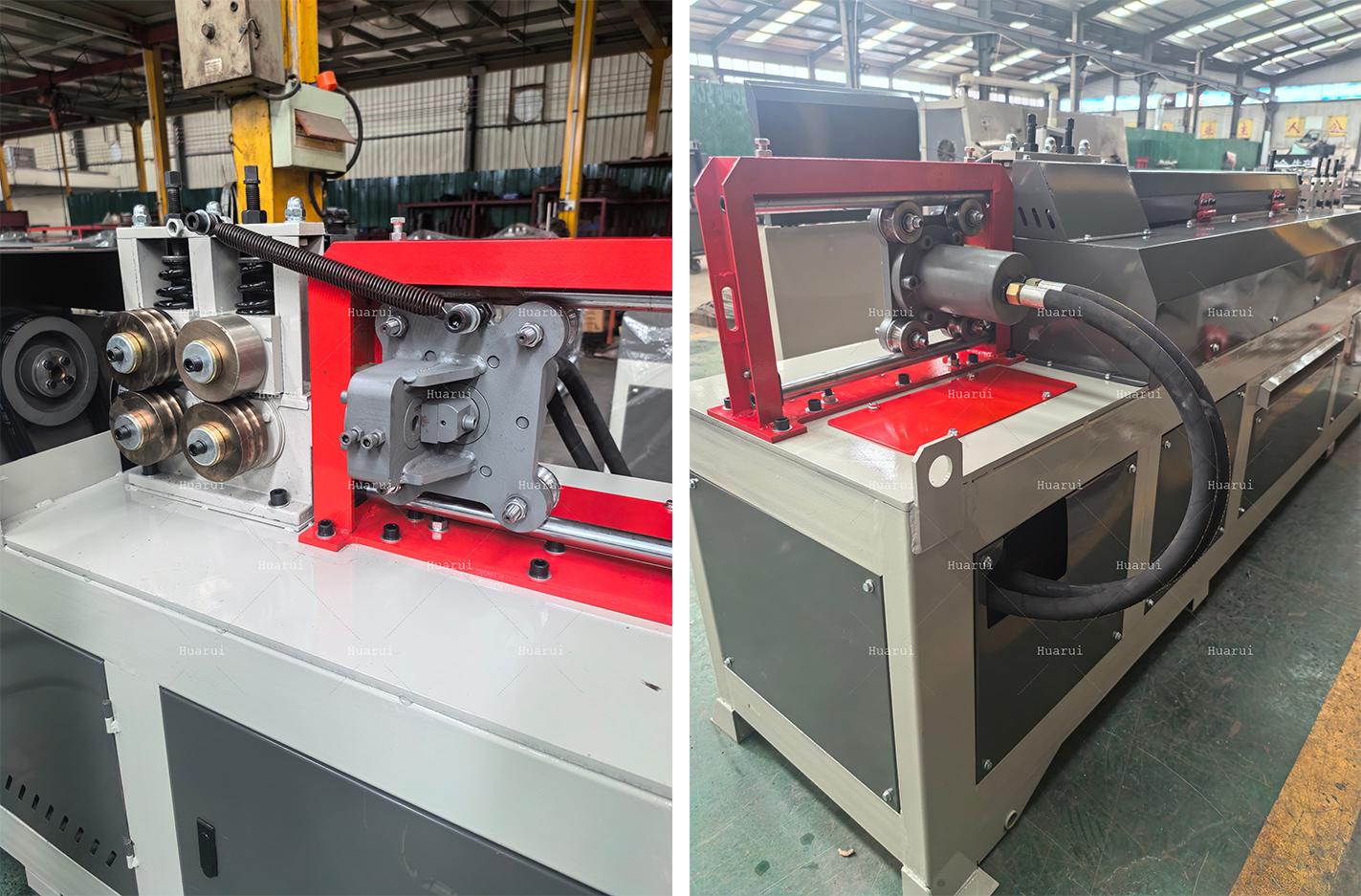

Cutting Mechanism

Use new patented oil cylinder, which is accurate and stable, with small error, long-lasting impact and fast knife return, increased shearing force, oil pressure overload protection, safe and reliable.

Technical Parameters

Model | GT4-12S | GT4-14 (0-70m) | GT6-16 (0-70m) |

Working scope | 4-12mm | 4-14mm | 6-16mm |

Working speed | 40-65m/min | 70m/min | 0-70m/min |

Processing range | 300-99.99mm | 0.01-99m | 0.01-99m |

Motor power | 5.5+9/11kw | 20.5kw | 27.5kw |

Motor speed | Two-speed motor | 1440r/min/frequency conversion | frequency conversion |

Straightening speed | High speed 65m/min Low speed 40m/min | 6mm thread steel 85m/min 8mm thread steel 93m/min 10mm thread steel 100m/min 12mm thread steel 50m/min (0-35Hz) 14mm round steel 30m/min (0-20Hz) | 6mm thread steel 58m/min 8mm thread steel 65m/min 10mm thread steel 70m/min 12mm thread steel 50m/min (0-35Hz) 14mm round steel 40m/min (0-20Hz) |

Machine weight | 900kg | 1200kg | 1400kg |

Dimensions | 2400*640*1160mm | 2960*600*1150mm | 3000*800*1220mm |

We also have dozens of other models of rebar straightening and cutting machines, and we offer customized services. Please tell me your requirements, and we will recommend the most suitable machine for you!!!

Product uses:

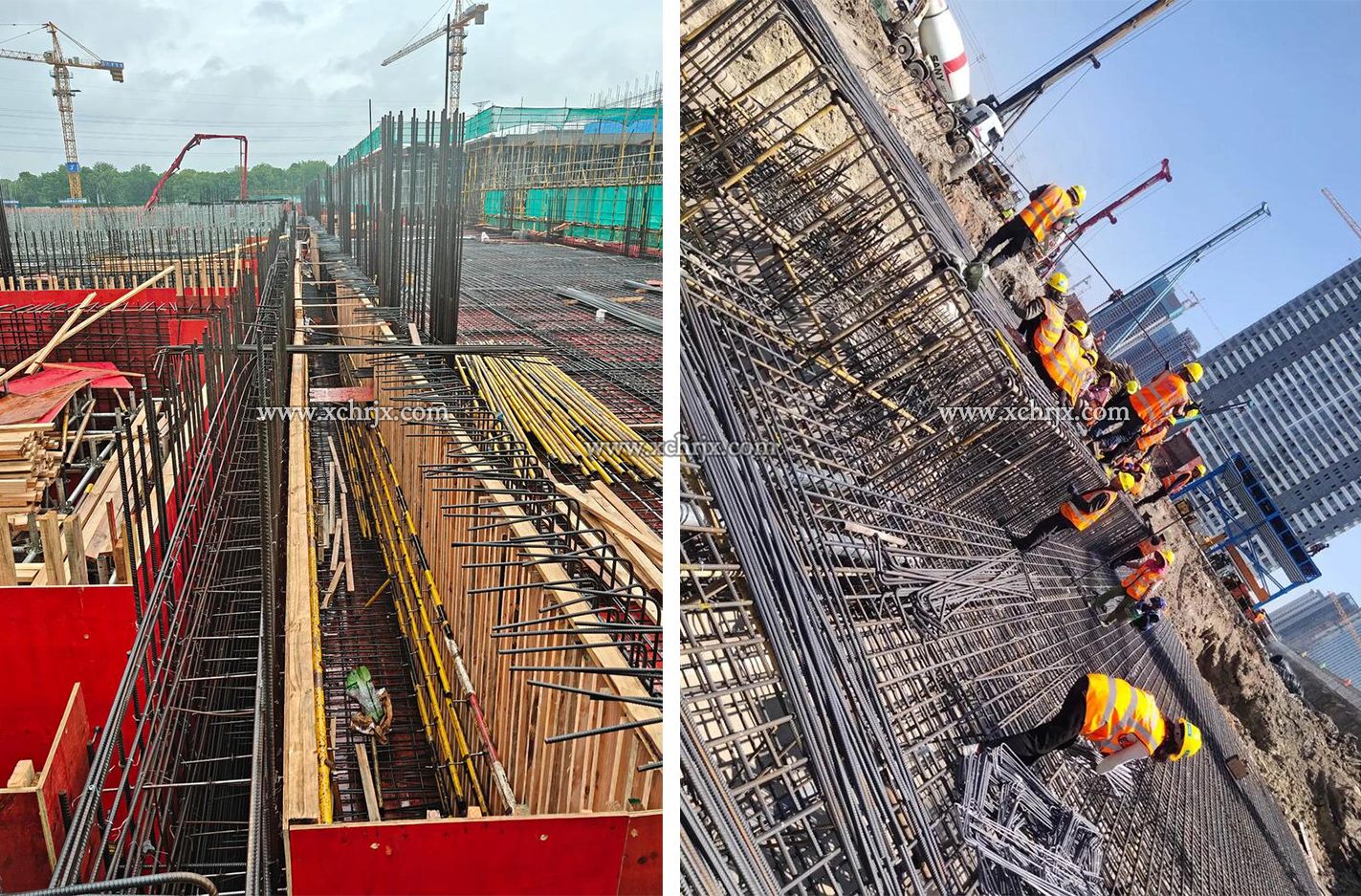

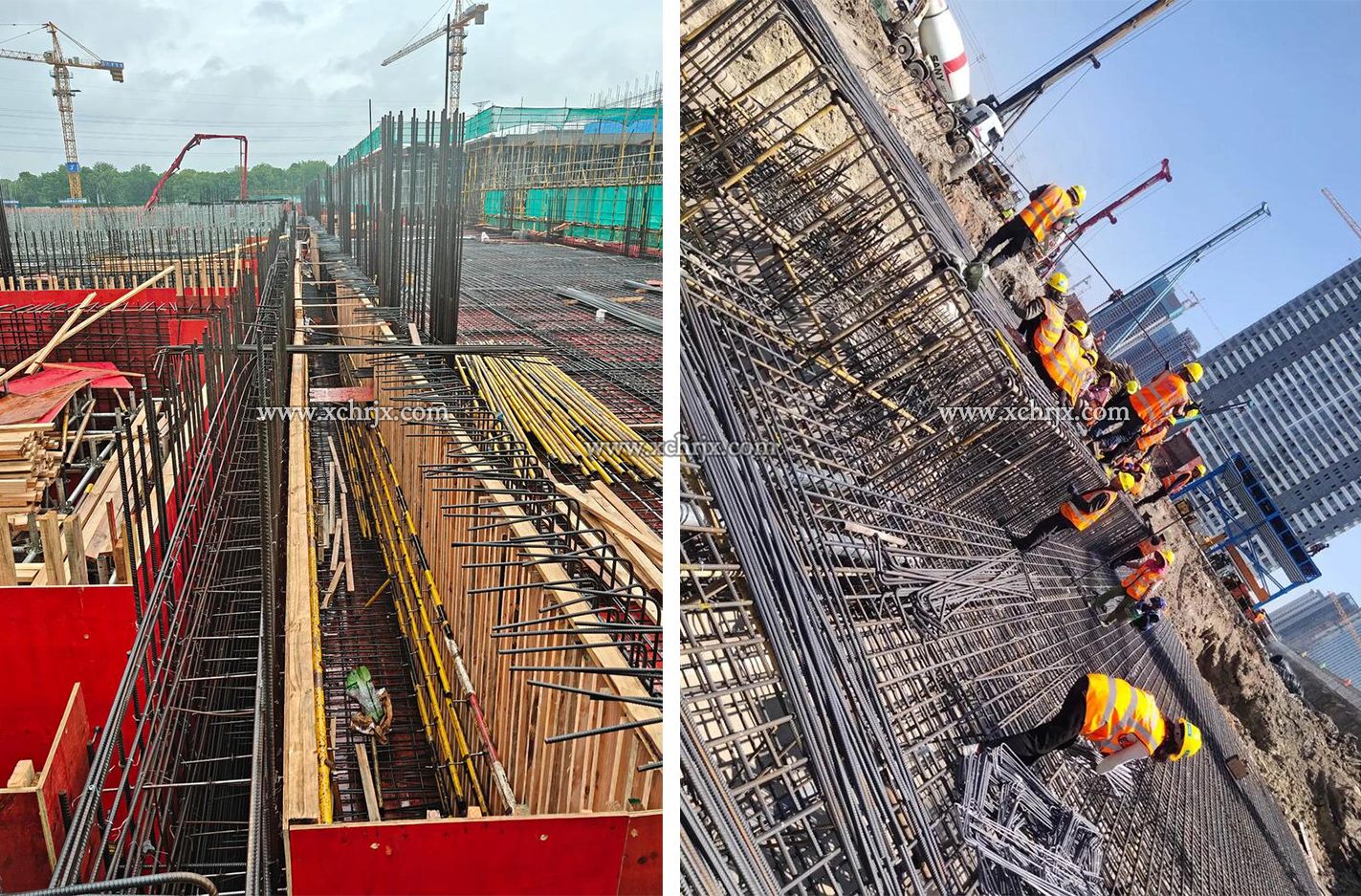

Widely used in construction engineering, highway bridges, precast concrete component plants, rebar mesh processing, and irregularly shaped mesh production, etc.

Fully automatic rebar straightening and cutting machines are core equipment with an extremely high return on investment in industrialized construction processes. They upgrade the traditional rebar processing model, which relied on manual labor, experience, and decentralized operations, to a modern production method characterized by CNC control, continuous operation, and high precision.

For rebar processing companies or large construction sites, purchasing such equipment not only means saving manpower but also ensures quality assurance, on-time completion, and reduced waste. Rebar straightener and cutter have become indispensable equipment in construction projects.

FAQ:

Q: Do you offer customize service?

A: Yes, we can customize machine according to your demands.

Q: How can I pay my order?

A: We accept T/T, LC,Western Union, Alibaba Online Payment to pay.

Q: Can you ship your machine to my country?

A: Yes, if you don't have shipping agent , we can ship machines to your nearest sea port.

Q: How many years exporting experience?

A: We have more than 16 years exporting experience, and we’ve exported our machines to more than 50 countries.

Q: Do you have any certificate?

A: We have CE certificate.

Q: How about your warranty?

A: 2 years. Normally, the general after-sale service may be as below.

1) The technical support is permanent.

2) The paid spares parts could be provided at any time,

3) Offer compensable installation and training service.

Product Introduction

Fully automatic rebar straightening and cutting machine is a metal wire processing equipment, also named as a wire straightening machine, bar straightening and cutting machine, CNC rebar straightening and cutting machine, Rebar Straightener and Cutter, Steel Bar Straightening & Cutting Machine, etc. It mainly processes coiled round rebar, coiled spiral rebar, and threaded rebar with diameters of Φ2-Φ16 mm, and can also process stainless steel wire, aluminum wire, cold-drawn wire, etc.

Our machine is equipped with a frequency converter, which can achieve 0-100m/min frequency conversion speed regulation, making it a high-speed rebar straightening and cutting machine.

Machine Core Components and Advantages: The Steel Bar CNC Straightening Cutting Machine consists of five main parts: a straightening mechanism, a traction mechanism, a cutting mechanism, a material unloading rack, and an electrical control system. Modern models generally adopt microcomputer/PLC control, hydraulic or wheel shear cutting, and servo motor traction.

Specially customized feed inlet

Prevent the steel bars from swinging and tangling, resulting in better stability.

Traction Mechanism

Made of alloy, it is wear-resistant and durable, and the auxiliary straightening mechanism achieves better straightening effect.

Straightening Mechanism

The straightening wheel is made of Cr12mov material and processed by vacuum heat treatment. It has a built-in dust-proof design to prevent oxide scale from damaging the bearing and is more durable.

Cutting Mechanism

Use new patented oil cylinder, which is accurate and stable, with small error, long-lasting impact and fast knife return, increased shearing force, oil pressure overload protection, safe and reliable.

Technical Parameters

Model | GT4-12S | GT4-14 (0-70m) | GT6-16 (0-70m) |

Working scope | 4-12mm | 4-14mm | 6-16mm |

Working speed | 40-65m/min | 70m/min | 0-70m/min |

Processing range | 300-99.99mm | 0.01-99m | 0.01-99m |

Motor power | 5.5+9/11kw | 20.5kw | 27.5kw |

Motor speed | Two-speed motor | 1440r/min/frequency conversion | frequency conversion |

Straightening speed | High speed 65m/min Low speed 40m/min | 6mm thread steel 85m/min 8mm thread steel 93m/min 10mm thread steel 100m/min 12mm thread steel 50m/min (0-35Hz) 14mm round steel 30m/min (0-20Hz) | 6mm thread steel 58m/min 8mm thread steel 65m/min 10mm thread steel 70m/min 12mm thread steel 50m/min (0-35Hz) 14mm round steel 40m/min (0-20Hz) |

Machine weight | 900kg | 1200kg | 1400kg |

Dimensions | 2400*640*1160mm | 2960*600*1150mm | 3000*800*1220mm |

We also have dozens of other models of rebar straightening and cutting machines, and we offer customized services. Please tell me your requirements, and we will recommend the most suitable machine for you!!!

Product uses:

Widely used in construction engineering, highway bridges, precast concrete component plants, rebar mesh processing, and irregularly shaped mesh production, etc.

Fully automatic rebar straightening and cutting machines are core equipment with an extremely high return on investment in industrialized construction processes. They upgrade the traditional rebar processing model, which relied on manual labor, experience, and decentralized operations, to a modern production method characterized by CNC control, continuous operation, and high precision.

For rebar processing companies or large construction sites, purchasing such equipment not only means saving manpower but also ensures quality assurance, on-time completion, and reduced waste. Rebar straightener and cutter have become indispensable equipment in construction projects.

FAQ:

Q: Do you offer customize service?

A: Yes, we can customize machine according to your demands.

Q: How can I pay my order?

A: We accept T/T, LC,Western Union, Alibaba Online Payment to pay.

Q: Can you ship your machine to my country?

A: Yes, if you don't have shipping agent , we can ship machines to your nearest sea port.

Q: How many years exporting experience?

A: We have more than 16 years exporting experience, and we’ve exported our machines to more than 50 countries.

Q: Do you have any certificate?

A: We have CE certificate.

Q: How about your warranty?

A: 2 years. Normally, the general after-sale service may be as below.

1) The technical support is permanent.

2) The paid spares parts could be provided at any time,

3) Offer compensable installation and training service.