Welcome to Xuchang Huarui Machinery Co.,Ltd.

| Availability: | |

|---|---|

| Quantity: | |

ZMC10-90C ZMC8-80C ZMC6-70C ZME10-110C ZME6-70C

Huarui

Hex Bolt Making Machine / Multistation Cold Heading Machine / Bolt Threading Machine

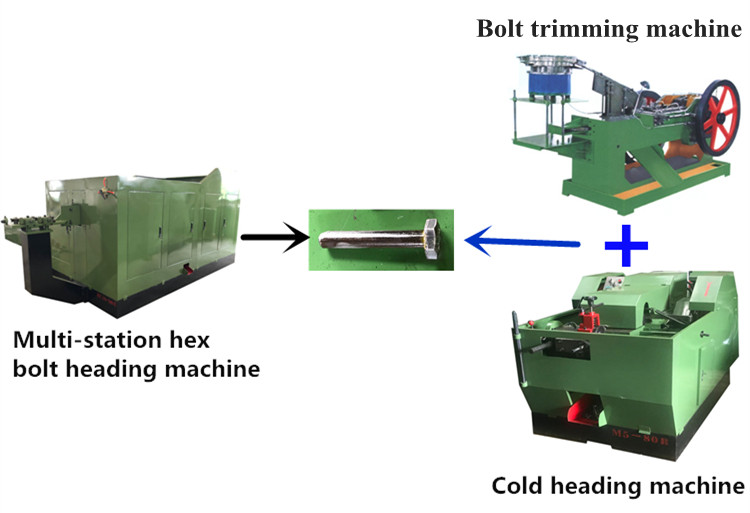

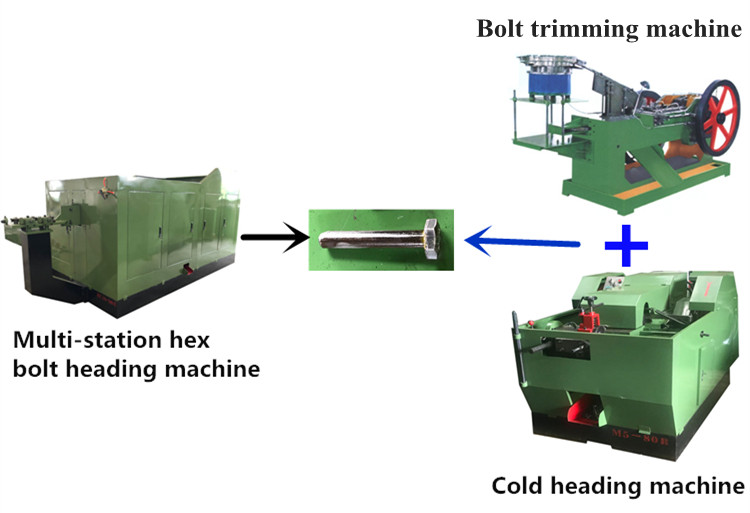

Advantage of multistation cold heading machine

Multistation cold heading machine equals to side cutting machine and bolt trimming machine. You can use one multistation cold heading machine to replace the two machines.

Bolt heading machine

Model | Max Screw Diameter(mm) | The main slide stroke (mm) | The longest withdraw material length(mm) | Main Motor(KW. Poles) | Oil pump(kw) | Capacity (pcs/min) | Weight (Ton) | PL*W*H (m) |

ZMC10-90C 3 die 3 blow | Φ12 | 160 | 120 | 2, 4 | 1.1 | 80-120 | 12 | 5.1×2.2×1.9 |

ZMC8-80C 3 die 3 blow | Φ10 | 150 | 120 | 15, 4 | 1.1 | 80-120 | 9.5 | 4.9×1.8×1.8 |

ZMC6-70C 3 die 3 blow | Φ8 | 130 | 90 | 7.5, 4 | 0.75 | 80-120 | 5 | 3.6×1.5×1.5 |

ZME10-110C 4 die 4 blow | Φ12 | 180 | 130 | 30, 4 | 1.1 | 80-120 | 14 | 6×2.3×2.1 |

ZME6-70C 4 die 4 blow | Φ8 | 130 | 90 | 15, 4 | 1.1 | 80-120 | 8 | 3.6×2.2×1.6 |

Full automatic thread rolling machine

This equipment adopts two thread profile thread rolling plate staggered 1/2 screw distance design, dead plate is fixed, movable plate equal to dead plate do straight line motion back and forth, when the work piece feed between two plates, movable plate move forward twist work piece, make its surface plastic deformation into thread.

Model | Max. Screw Dia (mm) | Max. Screw length (mm) | Motor (kw) | Capacity (pcs/min) | Weight (Ton) | Overall size (m) |

HR3-20A | M2.6 | 20 | 1.1 | 350 | 0.3 | 1.1*0.53*1.2 |

HR3-20B | M2.6 | 20 | 1.1 | 350 | 0.3 | 1.1*0.53*1.2 |

HR4-25A | M4 | 25 | 1.5 | 320 | 0.45 | 1.3*0.63*1.32 |

HR4-25B | M4 | 25 | 1.5 | 320 | 0.45 | 1.3*0.63*1.32 |

HR4-40A | M4 | 40 | 2.2/0.37 | 280 | 0.97 | 1.5*1.15*1.35 |

HR4-40B | M4 | 40 | 2.2/0.37 | 280 | 0.97 | 1.5*1.15*1.35 |

HR5-55B | M5 | 55 | 3+0.37 | 160 | 1.2 | 1.6*1.35*1.7 |

HR5-65A | M5 | 65 | 3+0.37 | 130 | 1.3 | 1.75*1.4*1.65 |

HR5-65B | M5 | 65 | 3+0.37 | 130 | 1.3 | 1.75*1.4*1.65 |

HR6-60A | M6 | 60 | 4/0.37 | 180 | 1.5 | 1.7*1.65*1.3 |

HR6-60B | M6 | 60 | 4/0.37 | 180 | 1.5 | 1.7*1.65*1.3 |

HR6-100B | M6 | 100 | 5.5+0.37 | 110 | 1.9 | 2.7*1.3*1.3 |

HR8-80B | M8 | 80 | 5.5/0.37 | 110 | 1.8 | 2.1*1.55*1.3 |

HR8-100B | M8 | 100 | 7.5+0.37 | 100 | 2.1 | 2.7*1.7*1.3 |

HR8-120B | M8 | 120 | 5.5 | 100 | 2.1 | 2.4*1.8*1.4 |

HR10-120B | M10 | 120 | 7.5 | 80 | 1.8 | 2.35*1.95*1.4 |

HR12-120B | M12 | 120 | 11 | 60 | 3 | 2.45*2*1.45 |

HR12-160B | M12 | 160 | 13 | 60 | 3 | 2.45*2*1.45 |

HR12-220B | M12 | 220 | 15 | 50 | 3.5 | 2.5*2*1.45 |

HR16-120B | M16 | 120 | 15 | 50 | 3.8 | 2.5*2.1*1.45 |

HR16-160B | M16 | 160 | 15 | 50 | 4 | 2.5*2.1*1.45 |

HR16-220B | M16 | 220 | 15 | 45 | 4.8 | 3.7*1.9*1.7 |

Bolt pictures

Packaging and shipping to overseas customers

Hex Bolt Making Machine / Multistation Cold Heading Machine / Bolt Threading Machine

Advantage of multistation cold heading machine

Multistation cold heading machine equals to side cutting machine and bolt trimming machine. You can use one multistation cold heading machine to replace the two machines.

Bolt heading machine

Model | Max Screw Diameter(mm) | The main slide stroke (mm) | The longest withdraw material length(mm) | Main Motor(KW. Poles) | Oil pump(kw) | Capacity (pcs/min) | Weight (Ton) | PL*W*H (m) |

ZMC10-90C 3 die 3 blow | Φ12 | 160 | 120 | 2, 4 | 1.1 | 80-120 | 12 | 5.1×2.2×1.9 |

ZMC8-80C 3 die 3 blow | Φ10 | 150 | 120 | 15, 4 | 1.1 | 80-120 | 9.5 | 4.9×1.8×1.8 |

ZMC6-70C 3 die 3 blow | Φ8 | 130 | 90 | 7.5, 4 | 0.75 | 80-120 | 5 | 3.6×1.5×1.5 |

ZME10-110C 4 die 4 blow | Φ12 | 180 | 130 | 30, 4 | 1.1 | 80-120 | 14 | 6×2.3×2.1 |

ZME6-70C 4 die 4 blow | Φ8 | 130 | 90 | 15, 4 | 1.1 | 80-120 | 8 | 3.6×2.2×1.6 |

Full automatic thread rolling machine

This equipment adopts two thread profile thread rolling plate staggered 1/2 screw distance design, dead plate is fixed, movable plate equal to dead plate do straight line motion back and forth, when the work piece feed between two plates, movable plate move forward twist work piece, make its surface plastic deformation into thread.

Model | Max. Screw Dia (mm) | Max. Screw length (mm) | Motor (kw) | Capacity (pcs/min) | Weight (Ton) | Overall size (m) |

HR3-20A | M2.6 | 20 | 1.1 | 350 | 0.3 | 1.1*0.53*1.2 |

HR3-20B | M2.6 | 20 | 1.1 | 350 | 0.3 | 1.1*0.53*1.2 |

HR4-25A | M4 | 25 | 1.5 | 320 | 0.45 | 1.3*0.63*1.32 |

HR4-25B | M4 | 25 | 1.5 | 320 | 0.45 | 1.3*0.63*1.32 |

HR4-40A | M4 | 40 | 2.2/0.37 | 280 | 0.97 | 1.5*1.15*1.35 |

HR4-40B | M4 | 40 | 2.2/0.37 | 280 | 0.97 | 1.5*1.15*1.35 |

HR5-55B | M5 | 55 | 3+0.37 | 160 | 1.2 | 1.6*1.35*1.7 |

HR5-65A | M5 | 65 | 3+0.37 | 130 | 1.3 | 1.75*1.4*1.65 |

HR5-65B | M5 | 65 | 3+0.37 | 130 | 1.3 | 1.75*1.4*1.65 |

HR6-60A | M6 | 60 | 4/0.37 | 180 | 1.5 | 1.7*1.65*1.3 |

HR6-60B | M6 | 60 | 4/0.37 | 180 | 1.5 | 1.7*1.65*1.3 |

HR6-100B | M6 | 100 | 5.5+0.37 | 110 | 1.9 | 2.7*1.3*1.3 |

HR8-80B | M8 | 80 | 5.5/0.37 | 110 | 1.8 | 2.1*1.55*1.3 |

HR8-100B | M8 | 100 | 7.5+0.37 | 100 | 2.1 | 2.7*1.7*1.3 |

HR8-120B | M8 | 120 | 5.5 | 100 | 2.1 | 2.4*1.8*1.4 |

HR10-120B | M10 | 120 | 7.5 | 80 | 1.8 | 2.35*1.95*1.4 |

HR12-120B | M12 | 120 | 11 | 60 | 3 | 2.45*2*1.45 |

HR12-160B | M12 | 160 | 13 | 60 | 3 | 2.45*2*1.45 |

HR12-220B | M12 | 220 | 15 | 50 | 3.5 | 2.5*2*1.45 |

HR16-120B | M16 | 120 | 15 | 50 | 3.8 | 2.5*2.1*1.45 |

HR16-160B | M16 | 160 | 15 | 50 | 4 | 2.5*2.1*1.45 |

HR16-220B | M16 | 220 | 15 | 45 | 4.8 | 3.7*1.9*1.7 |

Bolt pictures

Packaging and shipping to overseas customers