Welcome to Xuchang Huarui Machinery Co.,Ltd.

| Availability: | |

|---|---|

| Quantity: | |

Huarui Machinery

HD-90 High Speed Nail Making Machine Full Automatic Nail Machine

Highlight Advantages:

1.Long service life,no less than the traditional common nail making machine, for at least 10 years. White belt at low cost and long life which is 5-6 months without an incorrect operation.

2.Automatic oiling , few lubrication points, much less than traditional machines and other nail making machines on market. It is still very tidy when operating.

3.Double-mode double-punching die structure (Double molds, Double punch pin. One nail cutter, made of imported alloy, the service life is 2-3 times that of ordinary mold.

4. Reduce the cost of making nails. (the nail making speed is 800pcs / min, which effectively reduced 50% -70% nail labor work.

5. Reduce the cost of coiling nails (Effectively reduce 35%-45% coil nail labor work).

6. Greatly improve the weight of the product and reduce the production cost (Improvement of nailing and coil-nailing efficiency. Reduction of waste nails. The reduction of energy consumption, etc. at least effectively reduce the production cost of the nails by more than $20/ ton, which Improved the core competitive ability of the factory).

7. Power saving. The motor power is 7KW in total, and only 4KW/hour (inverter control) is used.

8. Increase the output : The capacity of high speed type is 3times compared with the common type.

Model | HD-90 automatic high speed nail making machine |

Nail diameter | 2.0-3.8mm |

Nail length | 38-93mm |

Nail making speed | 760--800pcs/min |

Motor power | 5.5KW+1.5KW (inverter control) |

Machine weight | 3500KG |

Dimension | 2200*1500*1200mm |

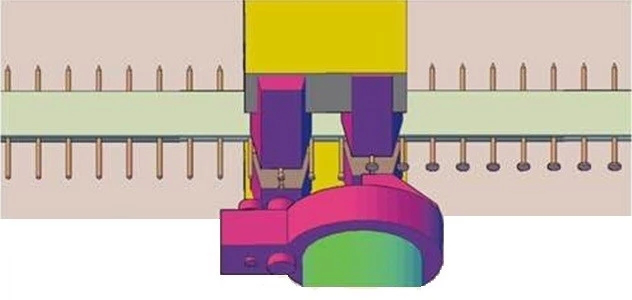

| Machine PartsName: punch characteristic: unique patent,twice stamping Dual-mode double-punch ①Nail head can be punched well even the shank is uneven. ②Big nail head. ③Nail head with out knock marks to ensure consistency. ④Uniform thickness of the nail cap diameter. ⑤Hollow design nail die,no small head,no ash blacking, no clip crumbs,no cracking,no frequent dies demolition. |

Machine Parts Name:Nail blade |

|

| Machine Parts Name:Feeding and rewinding structure ②Unique wire feeding and retreating combination,each nail through the wire feeding,cutting,wire retreating,three mechanical action,the nail will be completely separated from the nail shank to ensure quality. |

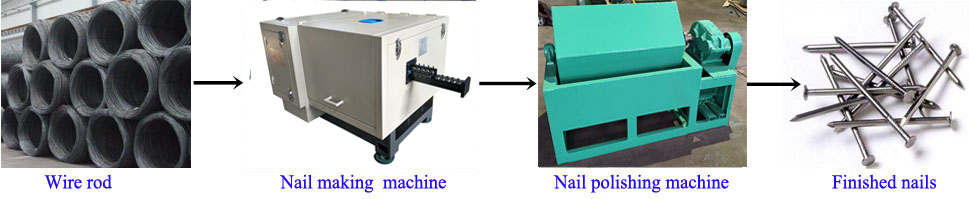

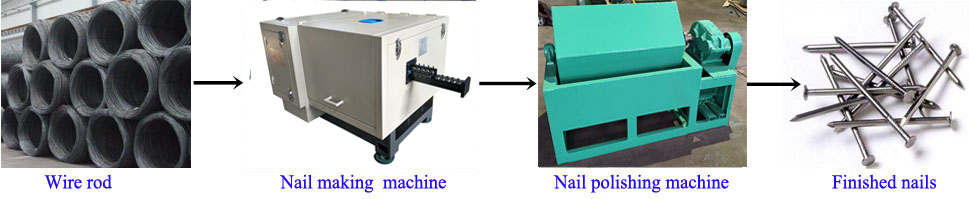

2.Nail polishing machine

Function: This machine is auxiliary equipment of nail making machine. When the nails have been made by the nail making machine, it will be not very bright. The user can use this machine to polish the nails to let it brighter, smoother and anti-rust.

3.Finished nails:

4.CE certification:

HD-90 High Speed Nail Making Machine Full Automatic Nail Machine

Highlight Advantages:

1.Long service life,no less than the traditional common nail making machine, for at least 10 years. White belt at low cost and long life which is 5-6 months without an incorrect operation.

2.Automatic oiling , few lubrication points, much less than traditional machines and other nail making machines on market. It is still very tidy when operating.

3.Double-mode double-punching die structure (Double molds, Double punch pin. One nail cutter, made of imported alloy, the service life is 2-3 times that of ordinary mold.

4. Reduce the cost of making nails. (the nail making speed is 800pcs / min, which effectively reduced 50% -70% nail labor work.

5. Reduce the cost of coiling nails (Effectively reduce 35%-45% coil nail labor work).

6. Greatly improve the weight of the product and reduce the production cost (Improvement of nailing and coil-nailing efficiency. Reduction of waste nails. The reduction of energy consumption, etc. at least effectively reduce the production cost of the nails by more than $20/ ton, which Improved the core competitive ability of the factory).

7. Power saving. The motor power is 7KW in total, and only 4KW/hour (inverter control) is used.

8. Increase the output : The capacity of high speed type is 3times compared with the common type.

Model | HD-90 automatic high speed nail making machine |

Nail diameter | 2.0-3.8mm |

Nail length | 38-93mm |

Nail making speed | 760--800pcs/min |

Motor power | 5.5KW+1.5KW (inverter control) |

Machine weight | 3500KG |

Dimension | 2200*1500*1200mm |

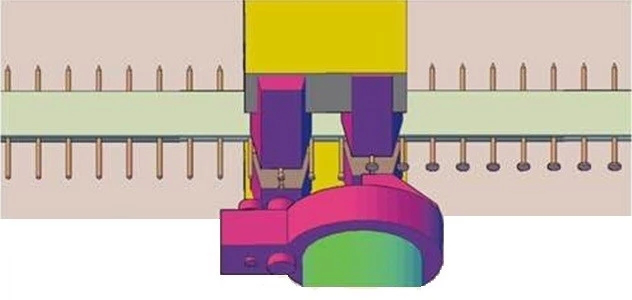

| Machine PartsName: punch characteristic: unique patent,twice stamping Dual-mode double-punch ①Nail head can be punched well even the shank is uneven. ②Big nail head. ③Nail head with out knock marks to ensure consistency. ④Uniform thickness of the nail cap diameter. ⑤Hollow design nail die,no small head,no ash blacking, no clip crumbs,no cracking,no frequent dies demolition. |

Machine Parts Name:Nail blade |

|

| Machine Parts Name:Feeding and rewinding structure ②Unique wire feeding and retreating combination,each nail through the wire feeding,cutting,wire retreating,three mechanical action,the nail will be completely separated from the nail shank to ensure quality. |

2.Nail polishing machine

Function: This machine is auxiliary equipment of nail making machine. When the nails have been made by the nail making machine, it will be not very bright. The user can use this machine to polish the nails to let it brighter, smoother and anti-rust.

3.Finished nails:

4.CE certification: