Welcome to Xuchang Huarui Machinery Co.,Ltd.

| Availability: | |

|---|---|

| Quantity: | |

Develop No.1, No,2, No,3, No,4, No,5

Huarui

Develop Series CNC Bar Bending Machine

Features:

1. This equipment adopts servo controlling system;

2. Automatically accomplish the functions of rebar's feeding, straighten, bending and cutting etc;

3. Max bending diameter of rebar is 12mm;

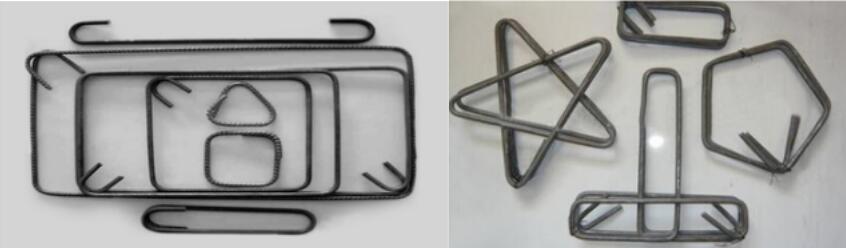

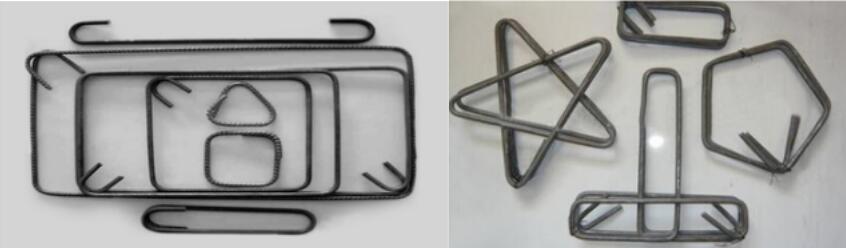

4. Continuously bend various stirrup of plane figure;

5. Bidirectional bending function,rebar stirrup bending machine can make special-shaped;

6. High efficiency and accurate processing precision.

7. Double roller synchronization with a wire feed system,easy to use and more convenient to study

Technical parameters:

Model No. | Develop NO. 1 | Develop NO. 2 | Develop NO. 3 | Develop NO.4 | Develop NO.5 | Develop NO.5C |

Single wire Working Capacity (mm) | Round steel bar: 4-10 | Round steel bar: 4-12 | Round steel bar: 4-14 | Round steel bar: 4-12 | Round steel bar: 5-14 | Round steel bar: 5-16 |

Ⅲ grade deformed steel bar: 4-8 | Ⅲ grade deformed steel bar: 4-10 | Ⅲ grade deformed steel bar: 4-14 | Ⅲ grade deformed steel bar: 4-10 | Ⅲ grade deformed steel bar: 5-14 | Ⅲ grade deformed steel bar: 5-16 | |

Double wire Working Capacity (mm) | Round steel Bar: 4-8 | Round steel Bar: 4-8 | Round steel bar: 4-10 | Round steel bar: 4-10 | Round steel bar: 5-10 | Round steel bar: 5-12 |

Ⅲ grade deformed steel bar: 4-6 | Ⅲ grade deformed steel bar: 4-8 | Ⅲ grade deformed steel bar: 4-10 | Ⅲ grade deformed steel bar: 4-8 | Ⅲ grade deformed steel bar: 5-10 | Ⅲ grade deformed steel bar: 5-12 | |

Production efficiency *(Pcs/hour) | 1600 | 1600 | 1800 | 1200 | 1800 | 1800 |

Max. bending angle | 180° | 180° | +-180° (bi-direction, Like I shaped) | +-180° (bi-direction, Like I shaped) | ±180° (bi-direction, Like I shaped) | ±180° |

Max. feeding speed(m/h) | 3600 | 3600 | 4500 | 4500 | 4500 | 4500 |

Max. bending speed(°/s) | 800 | 800 | 1000 | 1000 | 1000 | 1000 |

Length Error (mm) | ±1 | ±1 | ±1.5 | ±1 | ±1 | ±1 |

Angle Error(°) | ±1 | ±1 | ±1.5 | ±1 | ±1 | ±1 |

The height between axis of center of bending and ground(mm) | 1120 | 1180 | 1380 | 1180 | 1490 | 1500 |

Motor power(kw) | 12.5 | 20 | 28.5 | 24 | 30.5 | 38 |

L*W*H(m) | 2.57x0.97x1.62 | 3.27x0.92x1.7 | 4.1x1.1x2.1 | 3.5*1.1*1.7 | 3.56*1.08*2.03 (Host Machine) 3.46*0.9*0.2 (Receiving materials shelf) | 4.1x1.2x2.1 |

Weight(kg) | 1150 | 1350 | 2200 | 1500 | 2450 | 2800 |

More pictures:

Develop Series CNC Bar Bending Machine

Features:

1. This equipment adopts servo controlling system;

2. Automatically accomplish the functions of rebar's feeding, straighten, bending and cutting etc;

3. Max bending diameter of rebar is 12mm;

4. Continuously bend various stirrup of plane figure;

5. Bidirectional bending function,rebar stirrup bending machine can make special-shaped;

6. High efficiency and accurate processing precision.

7. Double roller synchronization with a wire feed system,easy to use and more convenient to study

Technical parameters:

Model No. | Develop NO. 1 | Develop NO. 2 | Develop NO. 3 | Develop NO.4 | Develop NO.5 | Develop NO.5C |

Single wire Working Capacity (mm) | Round steel bar: 4-10 | Round steel bar: 4-12 | Round steel bar: 4-14 | Round steel bar: 4-12 | Round steel bar: 5-14 | Round steel bar: 5-16 |

Ⅲ grade deformed steel bar: 4-8 | Ⅲ grade deformed steel bar: 4-10 | Ⅲ grade deformed steel bar: 4-14 | Ⅲ grade deformed steel bar: 4-10 | Ⅲ grade deformed steel bar: 5-14 | Ⅲ grade deformed steel bar: 5-16 | |

Double wire Working Capacity (mm) | Round steel Bar: 4-8 | Round steel Bar: 4-8 | Round steel bar: 4-10 | Round steel bar: 4-10 | Round steel bar: 5-10 | Round steel bar: 5-12 |

Ⅲ grade deformed steel bar: 4-6 | Ⅲ grade deformed steel bar: 4-8 | Ⅲ grade deformed steel bar: 4-10 | Ⅲ grade deformed steel bar: 4-8 | Ⅲ grade deformed steel bar: 5-10 | Ⅲ grade deformed steel bar: 5-12 | |

Production efficiency *(Pcs/hour) | 1600 | 1600 | 1800 | 1200 | 1800 | 1800 |

Max. bending angle | 180° | 180° | +-180° (bi-direction, Like I shaped) | +-180° (bi-direction, Like I shaped) | ±180° (bi-direction, Like I shaped) | ±180° |

Max. feeding speed(m/h) | 3600 | 3600 | 4500 | 4500 | 4500 | 4500 |

Max. bending speed(°/s) | 800 | 800 | 1000 | 1000 | 1000 | 1000 |

Length Error (mm) | ±1 | ±1 | ±1.5 | ±1 | ±1 | ±1 |

Angle Error(°) | ±1 | ±1 | ±1.5 | ±1 | ±1 | ±1 |

The height between axis of center of bending and ground(mm) | 1120 | 1180 | 1380 | 1180 | 1490 | 1500 |

Motor power(kw) | 12.5 | 20 | 28.5 | 24 | 30.5 | 38 |

L*W*H(m) | 2.57x0.97x1.62 | 3.27x0.92x1.7 | 4.1x1.1x2.1 | 3.5*1.1*1.7 | 3.56*1.08*2.03 (Host Machine) 3.46*0.9*0.2 (Receiving materials shelf) | 4.1x1.2x2.1 |

Weight(kg) | 1150 | 1350 | 2200 | 1500 | 2450 | 2800 |

More pictures: