Welcome to Xuchang Huarui Machinery Co.,Ltd.

| Color: | |

|---|---|

| Function: | |

| Bar size can be processed: | |

| Availability: | |

| Quantity: | |

Develop No.1, Develop No.2, Develop No.3, Develop No.4, Develop No.5

Huarui

Develop Series Automatic Bar Bending Machine

Develop No.1, Develop No.2, Develop No.3, Develop No.4, Develop No.5, Develop No.5C

Features:

1.Automatic wire feeding system ( CNC ).

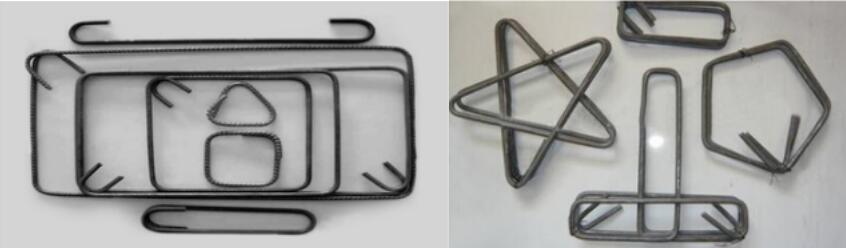

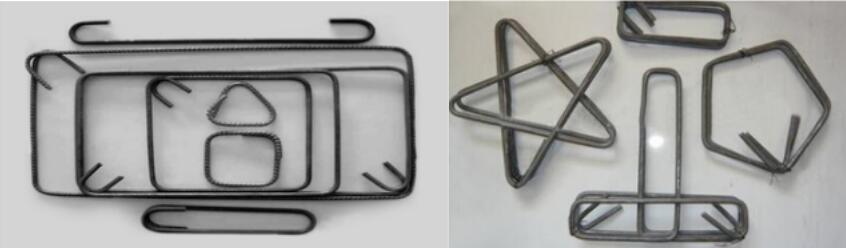

2.Large storage capacity can save 500 processing geometric graphics, high degree automation

3.Automatic double wire intake system, high processing efficiency

4. High power feeding motor to ensure bending bar accuracy.

5.The intelligent fault identification alarm system maintenance more convenient

6. Aerodynamic design observation door, easy adjustment and maintenance, and more security and fast.

7.Heavy-duty design line planes, equipped with a brake and buffer device can prevent chaotic lines caused by downtime

8. High quality special material and high treatment to make straightening wheels, traction wheels, the metering wheel, longer life with lower operating costs

9. Touch-screen console, easy to operate, and more fast

Technical parameters:

Model No. | Develop NO. 1 | Develop NO. 2 | Develop NO. 3 | Develop NO.4 | Develop NO.5 | Develop NO.5C |

Single wire Working Capacity (mm) | Round steel bar: 4-10 | Round steel bar: 4-12 | Round steel bar: 4-14 | Round steel bar: 4-12 | Round steel bar: 5-14 | Round steel bar: 5-16 |

Ⅲ grade deformed steel bar: 4-8 | Ⅲ grade deformed steel bar: 4-10 | Ⅲ grade deformed steel bar: 4-14 | Ⅲ grade deformed steel bar: 4-10 | Ⅲ grade deformed steel bar: 5-14 | Ⅲ grade deformed steel bar: 5-16 | |

Double wire Working Capacity (mm) | Round steel Bar: 4-8 | Round steel Bar: 4-8 | Round steel bar: 4-10 | Round steel bar: 4-10 | Round steel bar: 5-10 | Round steel bar: 5-12 |

Ⅲ grade deformed steel bar: 4-6 | Ⅲ grade deformed steel bar: 4-8 | Ⅲ grade deformed steel bar: 4-10 | Ⅲ grade deformed steel bar: 4-8 | Ⅲ grade deformed steel bar: 5-10 | Ⅲ grade deformed steel bar: 5-12 | |

Production efficiency *(Pcs/hour) | 1600 | 1600 | 1800 | 1200 | 1800 | 1800 |

Max. bending angle | 180° | 180° | +-180° (bi-direction, Like I shaped) | +-180° (bi-direction, Like I shaped) | ±180° (bi-direction, Like I shaped) | ±180° |

Max. feeding speed(m/h) | 3600 | 3600 | 4500 | 4500 | 4500 | 4500 |

Max. bending speed(°/s) | 800 | 800 | 1000 | 1000 | 1000 | 1000 |

Length Error (mm) | ±1 | ±1 | ±1.5 | ±1 | ±1 | ±1 |

Angle Error(°) | ±1 | ±1 | ±1.5 | ±1 | ±1 | ±1 |

The height between axis of center of bending and ground(mm) | 1120 | 1180 | 1380 | 1180 | 1490 | 1500 |

Motor power(kw) | 12.5 | 20 | 28.5 | 24 | 30.5 | 38 |

L*W*H(m) | 2.57x0.97x1.62 | 3.27x0.92x1.7 | 4.1x1.1x2.1 | 3.5*1.1*1.7 | 3.56*1.08*2.03 (Host Machine) 3.46*0.9*0.2 (Receiving materials shelf) | 4.1x1.2x2.1 |

Weight(kg) | 1150 | 1350 | 2200 | 1500 | 2450 | 2800 |

More Detailed Pictures:

Develop Series Automatic Bar Bending Machine

Develop No.1, Develop No.2, Develop No.3, Develop No.4, Develop No.5, Develop No.5C

Features:

1.Automatic wire feeding system ( CNC ).

2.Large storage capacity can save 500 processing geometric graphics, high degree automation

3.Automatic double wire intake system, high processing efficiency

4. High power feeding motor to ensure bending bar accuracy.

5.The intelligent fault identification alarm system maintenance more convenient

6. Aerodynamic design observation door, easy adjustment and maintenance, and more security and fast.

7.Heavy-duty design line planes, equipped with a brake and buffer device can prevent chaotic lines caused by downtime

8. High quality special material and high treatment to make straightening wheels, traction wheels, the metering wheel, longer life with lower operating costs

9. Touch-screen console, easy to operate, and more fast

Technical parameters:

Model No. | Develop NO. 1 | Develop NO. 2 | Develop NO. 3 | Develop NO.4 | Develop NO.5 | Develop NO.5C |

Single wire Working Capacity (mm) | Round steel bar: 4-10 | Round steel bar: 4-12 | Round steel bar: 4-14 | Round steel bar: 4-12 | Round steel bar: 5-14 | Round steel bar: 5-16 |

Ⅲ grade deformed steel bar: 4-8 | Ⅲ grade deformed steel bar: 4-10 | Ⅲ grade deformed steel bar: 4-14 | Ⅲ grade deformed steel bar: 4-10 | Ⅲ grade deformed steel bar: 5-14 | Ⅲ grade deformed steel bar: 5-16 | |

Double wire Working Capacity (mm) | Round steel Bar: 4-8 | Round steel Bar: 4-8 | Round steel bar: 4-10 | Round steel bar: 4-10 | Round steel bar: 5-10 | Round steel bar: 5-12 |

Ⅲ grade deformed steel bar: 4-6 | Ⅲ grade deformed steel bar: 4-8 | Ⅲ grade deformed steel bar: 4-10 | Ⅲ grade deformed steel bar: 4-8 | Ⅲ grade deformed steel bar: 5-10 | Ⅲ grade deformed steel bar: 5-12 | |

Production efficiency *(Pcs/hour) | 1600 | 1600 | 1800 | 1200 | 1800 | 1800 |

Max. bending angle | 180° | 180° | +-180° (bi-direction, Like I shaped) | +-180° (bi-direction, Like I shaped) | ±180° (bi-direction, Like I shaped) | ±180° |

Max. feeding speed(m/h) | 3600 | 3600 | 4500 | 4500 | 4500 | 4500 |

Max. bending speed(°/s) | 800 | 800 | 1000 | 1000 | 1000 | 1000 |

Length Error (mm) | ±1 | ±1 | ±1.5 | ±1 | ±1 | ±1 |

Angle Error(°) | ±1 | ±1 | ±1.5 | ±1 | ±1 | ±1 |

The height between axis of center of bending and ground(mm) | 1120 | 1180 | 1380 | 1180 | 1490 | 1500 |

Motor power(kw) | 12.5 | 20 | 28.5 | 24 | 30.5 | 38 |

L*W*H(m) | 2.57x0.97x1.62 | 3.27x0.92x1.7 | 4.1x1.1x2.1 | 3.5*1.1*1.7 | 3.56*1.08*2.03 (Host Machine) 3.46*0.9*0.2 (Receiving materials shelf) | 4.1x1.2x2.1 |

Weight(kg) | 1150 | 1350 | 2200 | 1500 | 2450 | 2800 |

More Detailed Pictures: