Welcome to Xuchang Huarui Machinery Co.,Ltd.

| Availability: | |

|---|---|

| Quantity: | |

Product Instruction

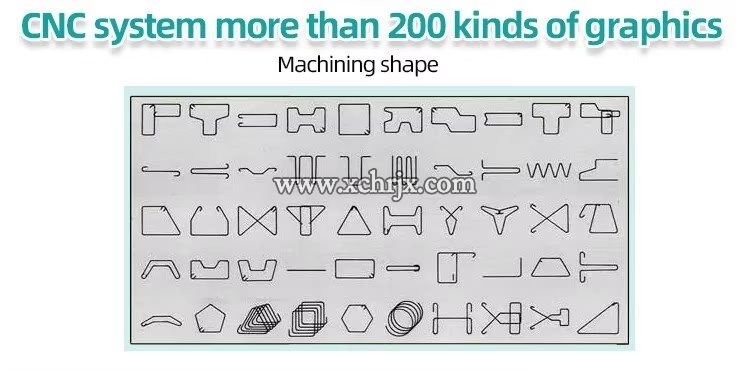

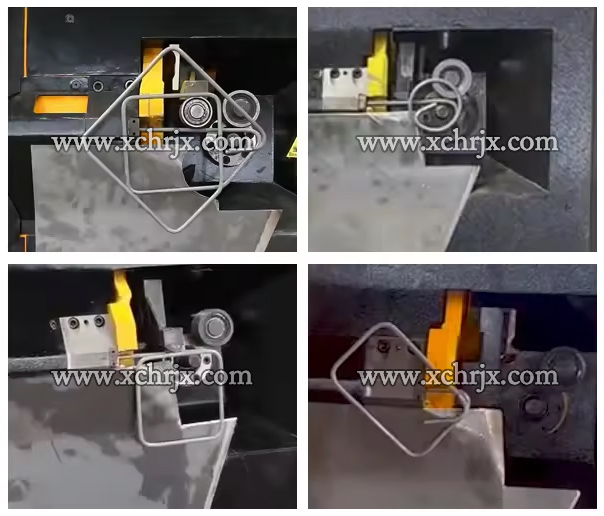

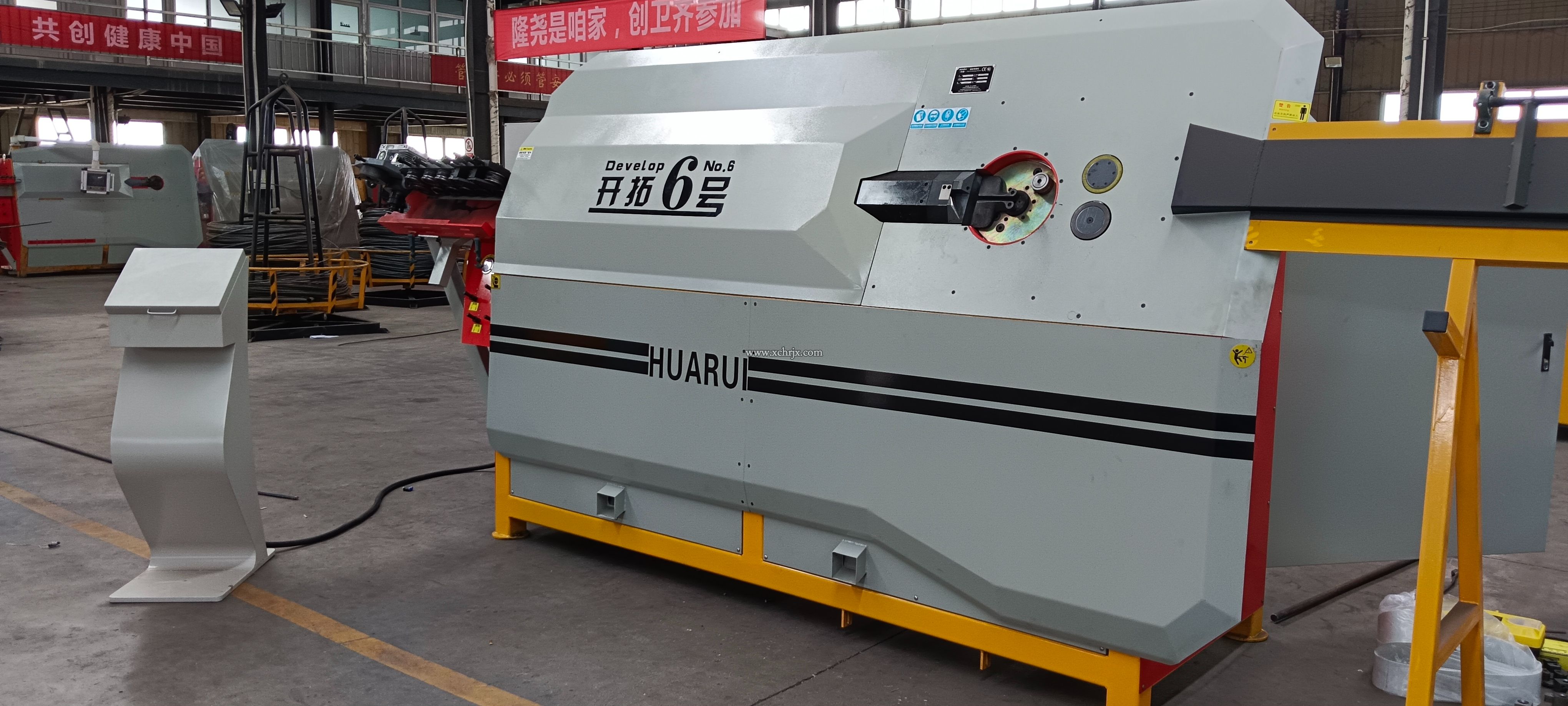

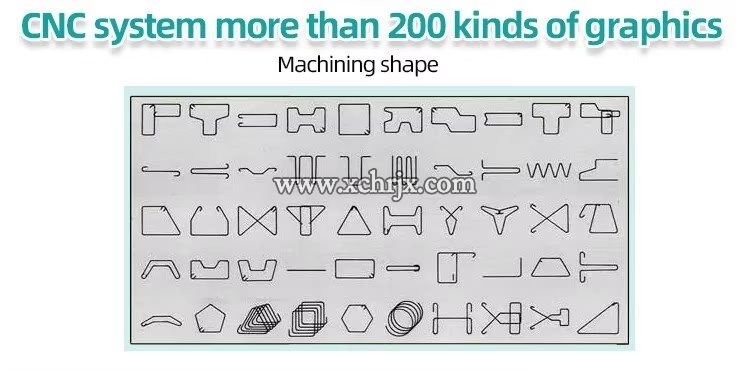

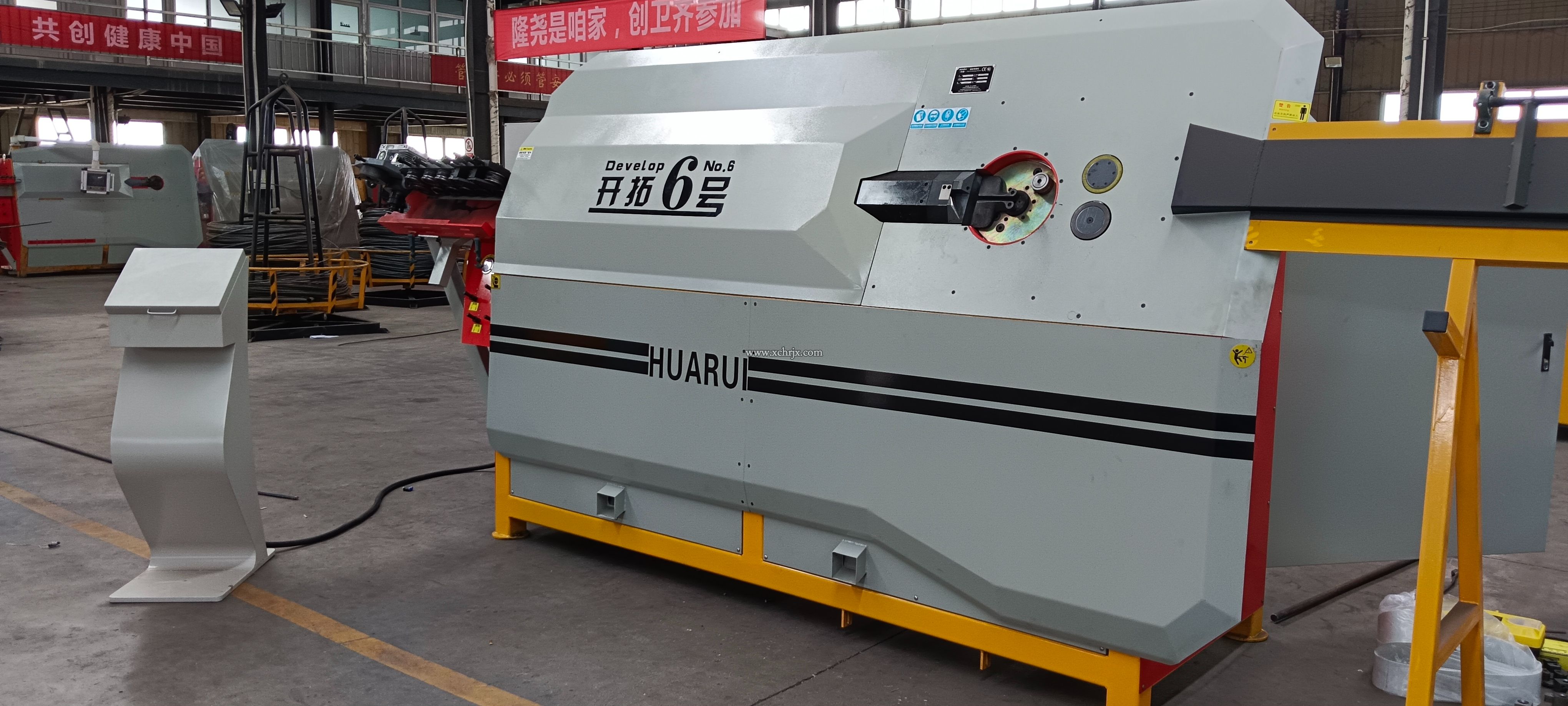

CNC rebar bending machines are core equipment in modern rebar processing plants,(especially construction sites, high-speed rail, bridges, and prefabricated housing projects). This equipment use programmable logic controller (PLC),can machine stirrup, rebar.it can automatically complete steel bar straighten.length,stirrup bend and cut. The max bend diameter is 16mm rebar, any 2d shapes can be manufactured in continuous manner. It is widely used for construction,steel processing plants and other area.

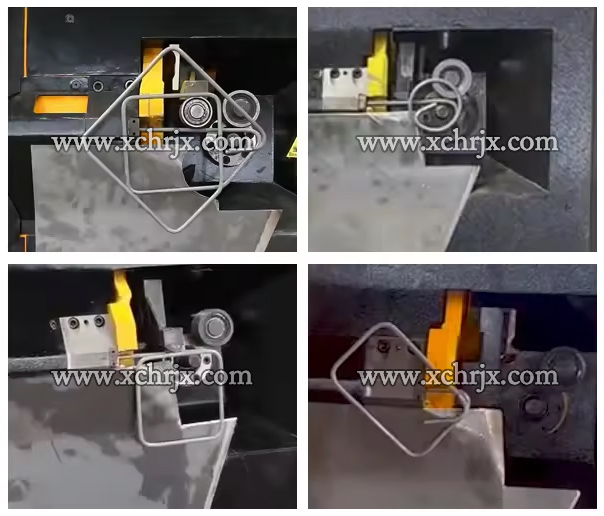

Finished product shape:

Finished product shape:

Advantages

Extremely high production efficiency

Speed: Production capacity is around 1600-2400pcs per hour (varies depending on the model).

Continuity: Coil feeding allows for unlimited continuous production without joint loss. Driven by a servo motor, the rebar is precisely fed into the bending mechanism according to the set length.

The feeding speed is synchronized with the bending speed, allowing for continuous operation.

Comparison: One CNC hoop bending machine can typically replace the workload of 5-8 skilled bending workers.

Stable Precision and Quality

Consistency: Dimensional tolerances remain perfectly consistent, whether it's the first or the thousandth finished product.

Precise Angles: The servo system controls the bending angle, eliminating springback errors or inaccurate angles common in manual bending.

Significantly Reduced Material Waste

Aesthetically pleasing Finished Products: No hammer marks or obvious scratches caused by manual bending.

Savings on Labor and Labor Intensity

Equipped with an automatic material receiving arm for free: The automatic material receiving robot can automatically receive materials, saving labor and improving work efficiency.

High Space Utilization

Using coiled material loading, the machine has a more compact layout than traditional "straight strip cutting + manual bending" or "large bending machines." The site is cleaner, meeting the requirements of modern construction and civilized production.

The essence of CNC rebar bending machines is to transform high-intensity manual labor into programmed, precise mechanical actions, thereby achieving the four goals of "saving manpower, materials, and land, and achieving high quality."

Specifications

Model No. | Develop NO.6 |

Single wire Working Capacity (mm) | Round steel bar: 6-18 |

Deformed steel bar: 6-16 | |

Double wire Working Capacity (mm) | Round steel bar: 6-14 |

Deformed steel bar: 6-12 | |

Production efficiency (Pcs/hour) | 2200-2400 |

Max. bending angle | Double direction Including banjin function

|

Max. feeding speed(m/h) | 4500 |

Max. bending speed(°/s) | 1000 |

Length Error (mm) | ±1 |

Angle Error(°) | ±1 |

Motor power(kw) | 38 |

L*W*H(m) | 4.15*1.4*2.1 |

Weight(kg) | 2800 |

Model No. | Develop NO.4 | Develop NO.5 |

Single wire Working Capacity (mm) | Round steel bar:4-12 | Round steel bar:6-14 |

Deformed steel bar:4-10 (Less 12mm) | Deformed steel bar:6-12 | |

Double wire Working Capacity (mm) | Round steel bar:4-8 | Round steel bar:6-10 |

Deformed steel bar:4-8 | Deformed steel bar:6-10 | |

Production efficiency(Pcs/hour) | 1200 | 1800 |

Max. bending angle | Double direction | Double direction Including banjin function

|

Max. feeding speed(m/h) | 4500 | 4500 |

Max. bending speed(°/s) | 1000 | 1000 |

Length Error(mm) | ±1 | ±1 |

Angle Error(°) | ±1 | ±1 |

Motor power(kw) | 24 | 30.5 |

L*W*H(m) | 3.5*1.1*1.7 | 3.56*1.08*2.03 |

Weight(kg) | 1500 | 2450 |

Application

Civil engineering and building construction

Infrastructure construction such as highways, bridges, and railways

Professional steel bar processing center

FAQ:

Q: Do you offer customize service?

A: Yes, we can customize machine according to your demands.

Q: How can I pay my order?

A: We accept T/T, LC,Western Union, Alibaba Online Payment to pay.

Q: Can you ship your machine to my country?

A: Yes, if you don't have shipping agent , we can ship machines to your nearest sea port.

Q: How many years exporting experience?

A: We have more than 16 years exporting experience, and we’ve exported our machines to more than 50 countries.

Q: Do you have any certificate?

A: We have CE certificate.

Q: How about your warranty?

A: 2 years. Normally, the general after-sale service may be as below.

1) The technical support is permanent.

2) The paid spares parts could be provided at any time,

3) Offer compensable installation and training service.

Product Instruction

CNC rebar bending machines are core equipment in modern rebar processing plants,(especially construction sites, high-speed rail, bridges, and prefabricated housing projects). This equipment use programmable logic controller (PLC),can machine stirrup, rebar.it can automatically complete steel bar straighten.length,stirrup bend and cut. The max bend diameter is 16mm rebar, any 2d shapes can be manufactured in continuous manner. It is widely used for construction,steel processing plants and other area.

Finished product shape:

Finished product shape:

Advantages

Extremely high production efficiency

Speed: Production capacity is around 1600-2400pcs per hour (varies depending on the model).

Continuity: Coil feeding allows for unlimited continuous production without joint loss. Driven by a servo motor, the rebar is precisely fed into the bending mechanism according to the set length.

The feeding speed is synchronized with the bending speed, allowing for continuous operation.

Comparison: One CNC hoop bending machine can typically replace the workload of 5-8 skilled bending workers.

Stable Precision and Quality

Consistency: Dimensional tolerances remain perfectly consistent, whether it's the first or the thousandth finished product.

Precise Angles: The servo system controls the bending angle, eliminating springback errors or inaccurate angles common in manual bending.

Significantly Reduced Material Waste

Aesthetically pleasing Finished Products: No hammer marks or obvious scratches caused by manual bending.

Savings on Labor and Labor Intensity

Equipped with an automatic material receiving arm for free: The automatic material receiving robot can automatically receive materials, saving labor and improving work efficiency.

High Space Utilization

Using coiled material loading, the machine has a more compact layout than traditional "straight strip cutting + manual bending" or "large bending machines." The site is cleaner, meeting the requirements of modern construction and civilized production.

The essence of CNC rebar bending machines is to transform high-intensity manual labor into programmed, precise mechanical actions, thereby achieving the four goals of "saving manpower, materials, and land, and achieving high quality."

Specifications

Model No. | Develop NO.6 |

Single wire Working Capacity (mm) | Round steel bar: 6-18 |

Deformed steel bar: 6-16 | |

Double wire Working Capacity (mm) | Round steel bar: 6-14 |

Deformed steel bar: 6-12 | |

Production efficiency (Pcs/hour) | 2200-2400 |

Max. bending angle | Double direction Including banjin function

|

Max. feeding speed(m/h) | 4500 |

Max. bending speed(°/s) | 1000 |

Length Error (mm) | ±1 |

Angle Error(°) | ±1 |

Motor power(kw) | 38 |

L*W*H(m) | 4.15*1.4*2.1 |

Weight(kg) | 2800 |

Model No. | Develop NO.4 | Develop NO.5 |

Single wire Working Capacity (mm) | Round steel bar:4-12 | Round steel bar:6-14 |

Deformed steel bar:4-10 (Less 12mm) | Deformed steel bar:6-12 | |

Double wire Working Capacity (mm) | Round steel bar:4-8 | Round steel bar:6-10 |

Deformed steel bar:4-8 | Deformed steel bar:6-10 | |

Production efficiency(Pcs/hour) | 1200 | 1800 |

Max. bending angle | Double direction | Double direction Including banjin function

|

Max. feeding speed(m/h) | 4500 | 4500 |

Max. bending speed(°/s) | 1000 | 1000 |

Length Error(mm) | ±1 | ±1 |

Angle Error(°) | ±1 | ±1 |

Motor power(kw) | 24 | 30.5 |

L*W*H(m) | 3.5*1.1*1.7 | 3.56*1.08*2.03 |

Weight(kg) | 1500 | 2450 |

Application

Civil engineering and building construction

Infrastructure construction such as highways, bridges, and railways

Professional steel bar processing center

FAQ:

Q: Do you offer customize service?

A: Yes, we can customize machine according to your demands.

Q: How can I pay my order?

A: We accept T/T, LC,Western Union, Alibaba Online Payment to pay.

Q: Can you ship your machine to my country?

A: Yes, if you don't have shipping agent , we can ship machines to your nearest sea port.

Q: How many years exporting experience?

A: We have more than 16 years exporting experience, and we’ve exported our machines to more than 50 countries.

Q: Do you have any certificate?

A: We have CE certificate.

Q: How about your warranty?

A: 2 years. Normally, the general after-sale service may be as below.

1) The technical support is permanent.

2) The paid spares parts could be provided at any time,

3) Offer compensable installation and training service.