Welcome to Xuchang Huarui Machinery Co.,Ltd.

| Availability: | |

|---|---|

| Quantity: | |

ZM series and HR series

Huarui

Automatic drywall screw making machine/self tapping screw machine

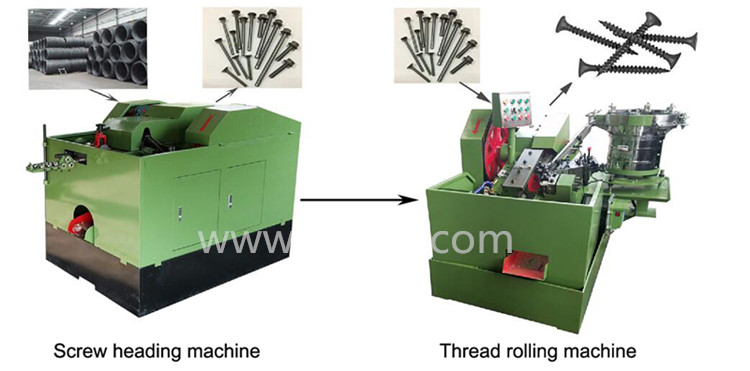

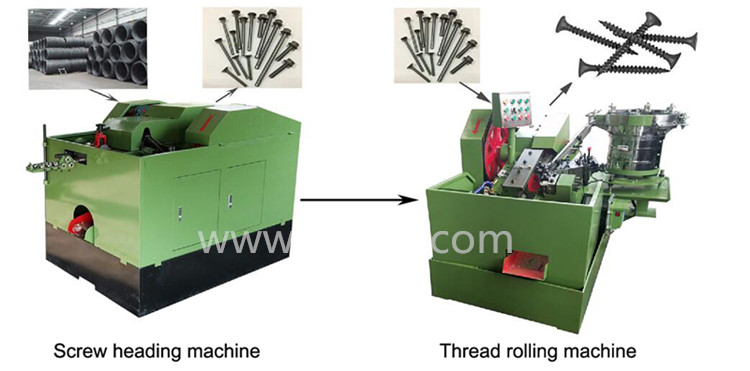

Process flow of making screws

Step1: Screw heading machine

ZM series cold heading machine adopts cold heading way to make the wire rod upsetting by double-click the whole mould form. Finished Feeding, straightening, cutting material, forming, discharging by one machine.

Model | Max. Screw Dia. (mm) | Max. Screw length (mm) | Capacity (pcs/min) | Motor (kw) | Weight (Ton) | Overall size (m) |

ZM3-18A/B | 3 | 18 | 160-180 | 0.75/0.37 | 0.6 | 1.3*0.75*0.9 |

ZM3-28A/B | 3 | 28 | 160-180 | 0.75/0.37 | 0.6 | 1.3*0.75*0.9 |

ZM4-28B | 4 | 28 | 120-160 | 1.5/0.37 | 0.97 | 1.5*0.9*0.9 |

ZM4-28D | 4.5 | 28 | 180-200 | 1.5/0.37 | 1.2 | 1.6*1*1.2 |

ZM4-40B | 4 | 40 | 120-150 | 1.5/0.37 | 0.97 | 1.6*1*1.2 |

ZM4-40D | 4.5 | 40 | 180-200 | 1.5/0.37 | 1.2 | 1.6*1.1*1.1 |

ZM5-40B | 6 | 40 | 120-150 | 2.2/0.37 | 1.8 | 1.8*1.1*1.1 |

ZM5-60B | 6 | 60 | 110-140 | 2.2/0.37 | 1.8 | 1.8*1.1*1.1 |

ZM5-80B | 6 | 80 | 80-100 | 2.2/0.37 | 1.9 | 2*1.1*1.2 |

ZM5-100B | 6 | 100 | 60-80 | 3/0.18 | 2.1 | 2.4*1.2*1.2 |

ZM5-120B | 6 | 120 | 50-70 | 3.6/0.37 | 2.3 | 2.8*1.3*1.3 |

ZM6-60B | 8 | 60 | 80-110 | 4/0.37 | 2.8 | 2.3*1.3*1.3 |

ZM6-100B | 8 | 100 | 60-90 | 4/0.37 | 2.7 | 2.3*1.3*1.3 |

ZM6-120B | 8 | 120 | 60-70 | 4/0.37 | 3 | 2.4*1.3*1.4 |

ZM6-170B | 8 | 170 | 40-70 | 4/0.37 | 3.7 | 3*1.3*1.5 |

ZM6-200B | 8 | 200 | 40-55 | 4/0.37 | 3.7 | 3*1.3*1.5 |

ZM8-120B | 10 | 120 | 50-90 | 5.5/0.37 | 4.6 | 3.4*1.5*1.5 |

ZM8-130B | 10 | 130 | 50-90 | 5.5/0.37 | 4.6 | 3.4*1.51.5 |

ZM8-130C | 10 | 130 | 50-90 | 5.5/0.37 | 4.6 | 3.4*1.51.5 |

ZM8-150C | 10 | 150 | 40-50 | 5.5/0.37 | 5 | 3.5*1.7*1.7 |

ZM8-200B | 10 | 200 | 25-60 | 7.5/0.37 | 6 | 3.8*1.6*1.7 |

ZM10-120B | 12 | 120 | 40-70 | 11/0.75 | 7 | 3.3*1.71.7 |

ZM10-170C | 12 | 170 | 40-60 | 11/0.75 | 7.5 | 4.2*1.81.7 |

ZM10-220C | 12 | 220 | 35-60 | 11/0.75 | 7.5 | 4.2*1.81.7 |

ZM10-250C | 12 | 250 | 30-45 | 11/0.75 | 8.5 | 5*1.8*1.7 |

ZM10-300C | 12 | 300 | 25-35 | 15/0.75 | 9 | 5*1.9*2.1 |

ZM10-360C | 12 | 360 | 20-30 | 15/0.75 | 12 | 6.7*2*2.6 |

ZM12-150C | 14 | 150 | 40-50 | 15/0.75 | 10 | 3.9*1.9*1.8 |

ZM12-250C | 14 | 250 | 35-50 | 15/0.75 | 11 | 5.3*2.2*1.9 |

ZM14-150C | 16 | 150 | 40-50 | 11/0.75 | 10 | 4.5*2.2*2.15 |

ZM14-250C | 16 | 250 | 35-45 | 15/0.75 | 11 | 5*2.2*2.15 |

Step2: Thread rolling machine

This equipment adopts two thread profile thread rolling plate staggered 1/2 screw distance design, dead plate is fixed, movable plate equal to dead plate do straight line motion back and forth, when the work piece feed between two plates, movable plate move forward twist work piece, make its surface plastic deformation into thread.

Thread rolling machine is portable, flexible, high efficiency and has some irreplaceable advantages compared with similar equipment, avoid the limit of lathe, drill or hand tapping, save time, labor, not easy to rotten teeth, screw tap not easy to break off.

The machine is easy to operate, convenient to maintenance, which greatly decrease the technical requirements for workers.

Model | Max. Screw Dia (mm) | Max. Screw length (mm) | Motor (kw) | Capacity (pcs/min) | Weight (Ton) | Overall size (m) |

HR3-20A | M2.6 | 20 | 1.1 | 350 | 0.3 | 1.1*0.53*1.2 |

HR3-20B | M2.6 | 20 | 1.1 | 350 | 0.3 | 1.1*0.53*1.2 |

HR4-25A | M4 | 25 | 1.5 | 320 | 0.45 | 1.3*0.63*1.32 |

HR4-25B | M4 | 25 | 1.5 | 320 | 0.45 | 1.3*0.63*1.32 |

HR4-40A | M4 | 40 | 2.2/0.37 | 280 | 0.97 | 1.5*1.15*1.35 |

HR4-40B | M4 | 40 | 2.2/0.37 | 280 | 0.97 | 1.5*1.15*1.35 |

HR5-55B | M5 | 55 | 3+0.37 | 160 | 1.2 | 1.6*1.35*1.7 |

HR5-65A | M5 | 65 | 3+0.37 | 130 | 1.3 | 1.75*1.4*1.65 |

HR5-65B | M5 | 65 | 3+0.37 | 130 | 1.3 | 1.75*1.4*1.65 |

HR6-60A | M6 | 60 | 4/0.37 | 180 | 1.5 | 1.7*1.65*1.3 |

HR6-60B | M6 | 60 | 4/0.37 | 180 | 1.5 | 1.7*1.65*1.3 |

HR6-100B | M6 | 100 | 5.5+0.37 | 110 | 1.9 | 2.7*1.3*1.3 |

HR8-80B | M8 | 80 | 5.5/0.37 | 110 | 1.8 | 2.1*1.55*1.3 |

HR8-100B | M8 | 100 | 7.5+0.37 | 100 | 2.1 | 2.7*1.7*1.3 |

HR8-120B | M8 | 120 | 5.5 | 100 | 2.1 | 2.4*1.8*1.4 |

HR10-120B | M10 | 120 | 7.5 | 80 | 1.8 | 2.35*1.95*1.4 |

HR12-120B | M12 | 120 | 11 | 60 | 3 | 2.45*2*1.45 |

HR12-160B | M12 | 160 | 13 | 60 | 3 | 2.45*2*1.45 |

HR12-220B | M12 | 220 | 15 | 50 | 3.5 | 2.5*2*1.45 |

HR16-120B | M16 | 120 | 15 | 50 | 3.8 | 2.5*2.1*1.45 |

HR16-160B | M16 | 160 | 15 | 50 | 4 | 2.5*2.1*1.45 |

HR16-220B | M16 | 220 | 15 | 45 | 4.8 | 3.7*1.9*1.7 |

Screw pictures

Packaging and shipping to overseas customers

Automatic drywall screw making machine/self tapping screw machine

Process flow of making screws

Step1: Screw heading machine

ZM series cold heading machine adopts cold heading way to make the wire rod upsetting by double-click the whole mould form. Finished Feeding, straightening, cutting material, forming, discharging by one machine.

Model | Max. Screw Dia. (mm) | Max. Screw length (mm) | Capacity (pcs/min) | Motor (kw) | Weight (Ton) | Overall size (m) |

ZM3-18A/B | 3 | 18 | 160-180 | 0.75/0.37 | 0.6 | 1.3*0.75*0.9 |

ZM3-28A/B | 3 | 28 | 160-180 | 0.75/0.37 | 0.6 | 1.3*0.75*0.9 |

ZM4-28B | 4 | 28 | 120-160 | 1.5/0.37 | 0.97 | 1.5*0.9*0.9 |

ZM4-28D | 4.5 | 28 | 180-200 | 1.5/0.37 | 1.2 | 1.6*1*1.2 |

ZM4-40B | 4 | 40 | 120-150 | 1.5/0.37 | 0.97 | 1.6*1*1.2 |

ZM4-40D | 4.5 | 40 | 180-200 | 1.5/0.37 | 1.2 | 1.6*1.1*1.1 |

ZM5-40B | 6 | 40 | 120-150 | 2.2/0.37 | 1.8 | 1.8*1.1*1.1 |

ZM5-60B | 6 | 60 | 110-140 | 2.2/0.37 | 1.8 | 1.8*1.1*1.1 |

ZM5-80B | 6 | 80 | 80-100 | 2.2/0.37 | 1.9 | 2*1.1*1.2 |

ZM5-100B | 6 | 100 | 60-80 | 3/0.18 | 2.1 | 2.4*1.2*1.2 |

ZM5-120B | 6 | 120 | 50-70 | 3.6/0.37 | 2.3 | 2.8*1.3*1.3 |

ZM6-60B | 8 | 60 | 80-110 | 4/0.37 | 2.8 | 2.3*1.3*1.3 |

ZM6-100B | 8 | 100 | 60-90 | 4/0.37 | 2.7 | 2.3*1.3*1.3 |

ZM6-120B | 8 | 120 | 60-70 | 4/0.37 | 3 | 2.4*1.3*1.4 |

ZM6-170B | 8 | 170 | 40-70 | 4/0.37 | 3.7 | 3*1.3*1.5 |

ZM6-200B | 8 | 200 | 40-55 | 4/0.37 | 3.7 | 3*1.3*1.5 |

ZM8-120B | 10 | 120 | 50-90 | 5.5/0.37 | 4.6 | 3.4*1.5*1.5 |

ZM8-130B | 10 | 130 | 50-90 | 5.5/0.37 | 4.6 | 3.4*1.51.5 |

ZM8-130C | 10 | 130 | 50-90 | 5.5/0.37 | 4.6 | 3.4*1.51.5 |

ZM8-150C | 10 | 150 | 40-50 | 5.5/0.37 | 5 | 3.5*1.7*1.7 |

ZM8-200B | 10 | 200 | 25-60 | 7.5/0.37 | 6 | 3.8*1.6*1.7 |

ZM10-120B | 12 | 120 | 40-70 | 11/0.75 | 7 | 3.3*1.71.7 |

ZM10-170C | 12 | 170 | 40-60 | 11/0.75 | 7.5 | 4.2*1.81.7 |

ZM10-220C | 12 | 220 | 35-60 | 11/0.75 | 7.5 | 4.2*1.81.7 |

ZM10-250C | 12 | 250 | 30-45 | 11/0.75 | 8.5 | 5*1.8*1.7 |

ZM10-300C | 12 | 300 | 25-35 | 15/0.75 | 9 | 5*1.9*2.1 |

ZM10-360C | 12 | 360 | 20-30 | 15/0.75 | 12 | 6.7*2*2.6 |

ZM12-150C | 14 | 150 | 40-50 | 15/0.75 | 10 | 3.9*1.9*1.8 |

ZM12-250C | 14 | 250 | 35-50 | 15/0.75 | 11 | 5.3*2.2*1.9 |

ZM14-150C | 16 | 150 | 40-50 | 11/0.75 | 10 | 4.5*2.2*2.15 |

ZM14-250C | 16 | 250 | 35-45 | 15/0.75 | 11 | 5*2.2*2.15 |

Step2: Thread rolling machine

This equipment adopts two thread profile thread rolling plate staggered 1/2 screw distance design, dead plate is fixed, movable plate equal to dead plate do straight line motion back and forth, when the work piece feed between two plates, movable plate move forward twist work piece, make its surface plastic deformation into thread.

Thread rolling machine is portable, flexible, high efficiency and has some irreplaceable advantages compared with similar equipment, avoid the limit of lathe, drill or hand tapping, save time, labor, not easy to rotten teeth, screw tap not easy to break off.

The machine is easy to operate, convenient to maintenance, which greatly decrease the technical requirements for workers.

Model | Max. Screw Dia (mm) | Max. Screw length (mm) | Motor (kw) | Capacity (pcs/min) | Weight (Ton) | Overall size (m) |

HR3-20A | M2.6 | 20 | 1.1 | 350 | 0.3 | 1.1*0.53*1.2 |

HR3-20B | M2.6 | 20 | 1.1 | 350 | 0.3 | 1.1*0.53*1.2 |

HR4-25A | M4 | 25 | 1.5 | 320 | 0.45 | 1.3*0.63*1.32 |

HR4-25B | M4 | 25 | 1.5 | 320 | 0.45 | 1.3*0.63*1.32 |

HR4-40A | M4 | 40 | 2.2/0.37 | 280 | 0.97 | 1.5*1.15*1.35 |

HR4-40B | M4 | 40 | 2.2/0.37 | 280 | 0.97 | 1.5*1.15*1.35 |

HR5-55B | M5 | 55 | 3+0.37 | 160 | 1.2 | 1.6*1.35*1.7 |

HR5-65A | M5 | 65 | 3+0.37 | 130 | 1.3 | 1.75*1.4*1.65 |

HR5-65B | M5 | 65 | 3+0.37 | 130 | 1.3 | 1.75*1.4*1.65 |

HR6-60A | M6 | 60 | 4/0.37 | 180 | 1.5 | 1.7*1.65*1.3 |

HR6-60B | M6 | 60 | 4/0.37 | 180 | 1.5 | 1.7*1.65*1.3 |

HR6-100B | M6 | 100 | 5.5+0.37 | 110 | 1.9 | 2.7*1.3*1.3 |

HR8-80B | M8 | 80 | 5.5/0.37 | 110 | 1.8 | 2.1*1.55*1.3 |

HR8-100B | M8 | 100 | 7.5+0.37 | 100 | 2.1 | 2.7*1.7*1.3 |

HR8-120B | M8 | 120 | 5.5 | 100 | 2.1 | 2.4*1.8*1.4 |

HR10-120B | M10 | 120 | 7.5 | 80 | 1.8 | 2.35*1.95*1.4 |

HR12-120B | M12 | 120 | 11 | 60 | 3 | 2.45*2*1.45 |

HR12-160B | M12 | 160 | 13 | 60 | 3 | 2.45*2*1.45 |

HR12-220B | M12 | 220 | 15 | 50 | 3.5 | 2.5*2*1.45 |

HR16-120B | M16 | 120 | 15 | 50 | 3.8 | 2.5*2.1*1.45 |

HR16-160B | M16 | 160 | 15 | 50 | 4 | 2.5*2.1*1.45 |

HR16-220B | M16 | 220 | 15 | 45 | 4.8 | 3.7*1.9*1.7 |

Screw pictures

Packaging and shipping to overseas customers