Welcome to Xuchang Huarui Machinery Co.,Ltd.

| Availability: | |

|---|---|

| Quantity: | |

Auto-400/450/560/560L

Huarui

Automatic Tire Recycling Machine/ Waste Tire Crumb Rubber Machine

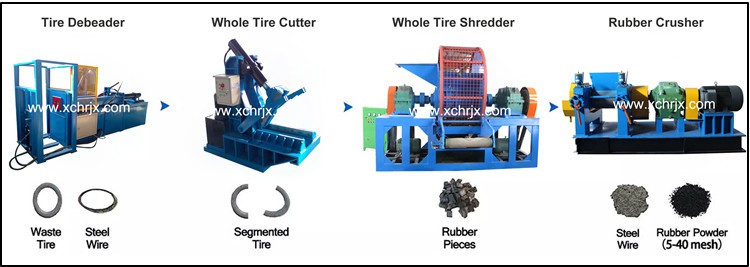

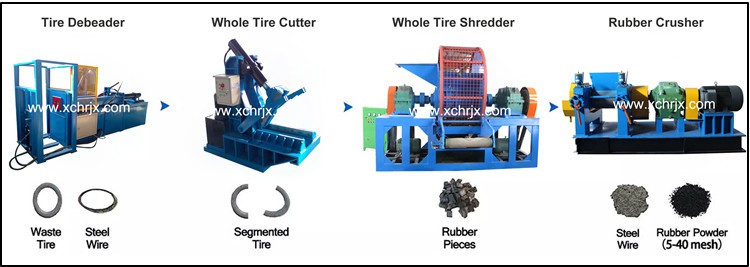

Draw steel wire from the tire ring by Tire wire drawing machine—if the diameter of tire is bigger than 900mm, can choose to use tire cutting machine to cut the tire to several pieces--- put the small tires or pieces into tire shredder to make tire blocks—put the tire blocks to the tire crusher to make rubber powder—finished rubber powder.

Step One:Pre-equipment for making rubber blocks

1. Tire debeader

TD-1200Tire wire drawing machine | |

Name | Technical parameter |

Feed size of tire(mm) | ≤φ1300 |

Capacity(tires/h) | 30-40 |

Power(KW) | 11 |

Overall dimensions(m) | 4.1*0.9*1.7 |

Equipment weight (T) | 1.8 |

Application: used to draw out the steel loops from the tire bead. | |

2.Tire cutting machine

TC-1200Tire cutting machine | |

Name | Technical parameter |

Feed size of tire(mm) | ≤φ1300 |

Capacity(tires/h) | 30-40 |

Power(KW) | 5.5/7.5 |

Overall dimensions(m) | 1.8*0.9*1.85 |

Equipment weight (T) | 1.5 |

Application: used to cut big tires to tree pieces or smaller pieces. | |

3.Tire shredder

TS-800 Tire shredder | |

| Name | Technical parameters |

| Output | 1-3tons/hour |

| Feed size of tires (mm) | ≤φ900 |

| Output size(mm) | ≤50*50 |

| Power (kw) | 22/30*2+4+1.5 |

Speed(r/min) | 15 |

Equipment weight | 9Ton |

Application: is used for cutting whole tire to 50*50mm rubber block. (Including 2 conveyor belts) | |

Step Two: Tire crusher set

Model No. | XKP-400 | XKP-450 | XKP-560 | XKP-560L |

Diameter of front roll | 400 mm (groove) | 450 mm (groove) | 560 mm (groove) | 560 mm (groove) |

Diameter of back roll | 400 mm (groove) | 450 mm (groove) | 510 mm (groove) | 560 mm (groove) |

Drum working length | 600mm | 760mm | 800mm | 1000mm |

Front roll liner speed | 34.5 m/min | 38.0 m/min | 40.6m/min | 44m/min |

Roll ratio | 1:2.5 | 1:2.5 | 1:2.5 | 1:2.5 |

Max roller spacing | 10 mm | 10 mm | 10 mm | 10mm |

Motor power | 45KW/55KW | 75KW /90KW | 90KW/110KW | 132KW/160KW |

Weight | 8.5 T | 11T | 17.5T | 21T |

L*W*H | 4.3*1.8*1.6m | 4.6*2.0*1.65m | 5.3*2.0*1.7m | 5.6*2.0*1.7m |

Tips: Both rollers are grooved which can improve the output. Roller material is Alloy 5Cr6MnMo. There are 8 pieces bearing inside the machine , all rolling bearing. | ||||

Highlight advantages

Our certificate

Automatic Tire Recycling Machine/ Waste Tire Crumb Rubber Machine

Draw steel wire from the tire ring by Tire wire drawing machine—if the diameter of tire is bigger than 900mm, can choose to use tire cutting machine to cut the tire to several pieces--- put the small tires or pieces into tire shredder to make tire blocks—put the tire blocks to the tire crusher to make rubber powder—finished rubber powder.

Step One:Pre-equipment for making rubber blocks

1. Tire debeader

TD-1200Tire wire drawing machine | |

Name | Technical parameter |

Feed size of tire(mm) | ≤φ1300 |

Capacity(tires/h) | 30-40 |

Power(KW) | 11 |

Overall dimensions(m) | 4.1*0.9*1.7 |

Equipment weight (T) | 1.8 |

Application: used to draw out the steel loops from the tire bead. | |

2.Tire cutting machine

TC-1200Tire cutting machine | |

Name | Technical parameter |

Feed size of tire(mm) | ≤φ1300 |

Capacity(tires/h) | 30-40 |

Power(KW) | 5.5/7.5 |

Overall dimensions(m) | 1.8*0.9*1.85 |

Equipment weight (T) | 1.5 |

Application: used to cut big tires to tree pieces or smaller pieces. | |

3.Tire shredder

TS-800 Tire shredder | |

| Name | Technical parameters |

| Output | 1-3tons/hour |

| Feed size of tires (mm) | ≤φ900 |

| Output size(mm) | ≤50*50 |

| Power (kw) | 22/30*2+4+1.5 |

Speed(r/min) | 15 |

Equipment weight | 9Ton |

Application: is used for cutting whole tire to 50*50mm rubber block. (Including 2 conveyor belts) | |

Step Two: Tire crusher set

Model No. | XKP-400 | XKP-450 | XKP-560 | XKP-560L |

Diameter of front roll | 400 mm (groove) | 450 mm (groove) | 560 mm (groove) | 560 mm (groove) |

Diameter of back roll | 400 mm (groove) | 450 mm (groove) | 510 mm (groove) | 560 mm (groove) |

Drum working length | 600mm | 760mm | 800mm | 1000mm |

Front roll liner speed | 34.5 m/min | 38.0 m/min | 40.6m/min | 44m/min |

Roll ratio | 1:2.5 | 1:2.5 | 1:2.5 | 1:2.5 |

Max roller spacing | 10 mm | 10 mm | 10 mm | 10mm |

Motor power | 45KW/55KW | 75KW /90KW | 90KW/110KW | 132KW/160KW |

Weight | 8.5 T | 11T | 17.5T | 21T |

L*W*H | 4.3*1.8*1.6m | 4.6*2.0*1.65m | 5.3*2.0*1.7m | 5.6*2.0*1.7m |

Tips: Both rollers are grooved which can improve the output. Roller material is Alloy 5Cr6MnMo. There are 8 pieces bearing inside the machine , all rolling bearing. | ||||

Highlight advantages

Our certificate